FlexPAK 800/1000

23

EN

See Section

for more information about each mode.

How the unit moves from one operation mode to another is explained below. See also

Figure

for a flow chart showing how the unit goes through its four different operation

modes.

As discussed in Section

, when the unit is in Off mode, the unit can be put

into Standby mode with its motor off and the Filter Cleaning Valve (FCV) closed by pressing

the Standby/Running button. While the unit is in Standby mode, the unit can be put back

into Off mode again by pressing the Standby/Running button.

The unit goes from Standby mode into Running mode when it receives a pilot signal by a

valve being opened at one or more work stations (in other words, someone starts to work).

The unit’s motor is now on and the FCV is closed. The DIR_Time and SSR_Time timers are

not started, see Sections

‘7.2.2 DIR_Time’ and ‘7.2.1 SSR_Time’

The unit stays in Running mode as long as there is an active pilot signal. However, the unit

can still be put into Off mode by pressing the Standby/Running button.

Note that if only one workstation is connected to the unit, or if only one work station is

in use and work stops at that one station, the pilot signal stops. If there is more than one

work station connected to the unit, and more than one work station is in use, the pilot

signal only stops if work stops at all workstations (in other words, all valves close).

When the pilot signal stops, the DIR and SSR timers start. If work resumes at one or more

work stations within 10 seconds, the unit stays in Running mode. The DIR and SSR timers

are reset back to zero and are stopped.

If DIR_Time is set for 10 seconds (default), and the pause in work is longer than 10 seconds,

DIR_Time elapses. The unit then goes into Idling mode with its motor on and the FCV open.

If a new pilot signal is sent within 12 minutes, the unit goes back into Running mode. The

DIR and SSR timers are again reset to zero and are stopped. However, if SSR_Time is set for

12 minutes, which is the default setting, and there is no new pilot signal within 12 minutes,

SSR_Time also elapses.

The unit then goes into Standby mode until it either receives a new pilot signal that puts

the unit back into Running mode, or the unit is turned off (in other words, put into Off

mode) by the weekly timer, see

, or by pressing the Standby/Running

button.

6

PLC messages

The following sections show the different status, warning and alarm messages that can be

seen in the PLC display. See also the PLC Settings Manual and the Installation and Service

Manual.

NOTE!

If a message is displayed that is not shown in this user manual, see the PLC Settings

Manual for more information.

NOTE!

If a warning or alarm is displayed that is not shown in this user manual, see the

PLC Settings Manual for more information and contact a Nederman authorized service

technician.

6.1

Status messages

The following status messages give information about what mode the unit is in or what

routine service is being performed.

Содержание FlexPAK 1000

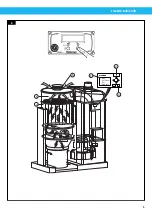

Страница 7: ...FlexPAK 800 1000 7 3 13 12 10 9 7 8 2 1 3 4 6 5 11 4 11 7 8 9 12 13 16 15 14 18 19 10 17 5 15 20 ...

Страница 8: ...FlexPAK 800 1000 8 1 2 3 4 5 6 7 14 13 12 11 9 8 10 7 6 ...

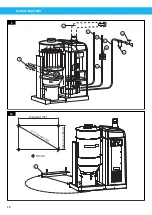

Страница 10: ...FlexPAK 800 1000 10 9 10 1643 1mm 65 662 1mm 26 2 1771 4 1mm 70 Ø13mm 2 1 4 5 6 8 7 9 3 1 ...

Страница 11: ...FlexPAK 800 1000 11 11 12 14 13 ...

Страница 12: ...FlexPAK 800 1000 12 1 0m 39 4 A B C 16 17 15 Min 2 1m 83 A A A A C ...

Страница 14: ...FlexPAK 800 1000 14 ...

Страница 55: ...FlexPAK 800 1000 55 CS ...

Страница 76: ...FlexPAK 800 1000 DA 76 ...

Страница 97: ...FlexPAK 800 1000 97 DE ...

Страница 98: ...FlexPAK 800 1000 DE 98 ...

Страница 119: ...FlexPAK 800 1000 119 ES ...

Страница 120: ...FlexPAK 800 1000 ES 120 ...

Страница 141: ...FlexPAK 800 1000 141 FI ...

Страница 142: ...FlexPAK 800 1000 FI 142 ...

Страница 163: ...FlexPAK 800 1000 163 FR ...

Страница 164: ...FlexPAK 800 1000 FR 164 ...

Страница 205: ...FlexPAK 800 1000 205 IT ...

Страница 206: ...FlexPAK 800 1000 IT 206 ...

Страница 227: ...FlexPAK 800 1000 227 NL ...

Страница 228: ...FlexPAK 800 1000 NL 228 ...

Страница 270: ...FlexPAK 800 1000 PL 270 ...

Страница 292: ...FlexPAK 800 1000 PT 292 ...

Страница 314: ...FlexPAK 800 1000 RU 314 ...

Страница 335: ...FlexPAK 800 1000 335 SV ...

Страница 336: ...FlexPAK 800 1000 SV 336 ...

Страница 354: ...FlexPAK 800 1000 ZH 354 9 4 1 环保信息 以下环保信息对 FlexPAK 800 1000 有效 在控制设备中采用无镉和无卤继电器 无溶剂清洗和清漆 93 6 可回收 根据需要可提供环保产品声明 ...

Страница 356: ...FlexPAK 800 1000 ZH 356 ...

Страница 357: ......

Страница 358: ...www nederman com ...