Installation Guide for NCPE Split-System Condensing Units

9

Evacuation

1.

Connect the vacuum pump to the service ports of the liquid

line and the vapor line service valves. If the vacuum pump lines

do not contain shut-off valves, hook up the vacuum pump

through a manifold gauge set, as the vacuum pump lines must

be closed for step 4 below.

a. If the evacuation is being performed on a new system

installation, the condensing unit service valves should be

kept in the closed position. The vacuum pump will then

be able to evacuate the refrigerant lines and evaporator

coil.

b. If the evacuation is being performed on an installation

where the condensing unit factory charge has been lost,

the service valves should be opened.

2.

Following the vacuum pump manufacturer’s instructions,

allow the pump to operate until the system has been evacuated

down to 300 microns.

NOTE: Check for leaks if unable to get to 300 microns.

3.

Allow the pump to continue running an additional 15 minutes.

Turn off the pump and leave connections secured. After 10

minutes if system fails to hold 500 microns or less, check all

connections for tight fit and repeat evacuation procedure.

4.

Isolate the vacuum pump by closing the shut-off valves on

vacuum pump lines or test gauge manifold.

5.

Open the service valves. Opening the service valves will allow

the refrigerant in the condensing unit to enter the refrigerant

lines and evaporator coil. The vacuum pump can now be

disconnected.

Electrical Connections

NOTE:

Make certain that the volts, hertz, and phase correspond

to that specified on the unit rating plate, and that the service

provided by the utility is sufficient to handle the additional load

imposed by this equipment.

Make all electrical connections in accordance with the National

Electrical Code and any pertinent local codes or ordinances.

Use a separate branch electrical circuit for this unit. Locate a

disconnecting means within sight of and readily accessible to

the unit.

a. Line Voltage Connections

b. Connect the single phase power supply to unit contactor

terminal L1 and L2

c. Connect ground wire to lug

d. Low Voltage Connections

Consult the indoor unit installation instructions for thermostat

connections.

Use a 2-wire thermostat cable between the units.

When locating the room thermostat, it should be in the natural

circulating path of room air. Avoid locations where the thermostat

would be exposed to cold air infiltration; drafts from windows,

doors or other openings leading to the outside; exposure to air

currents from warm-or-cold air registers or to exposure where

the natural circulation of the air is cut off, such as behind doors,

above or below mantels, shelves, etc.

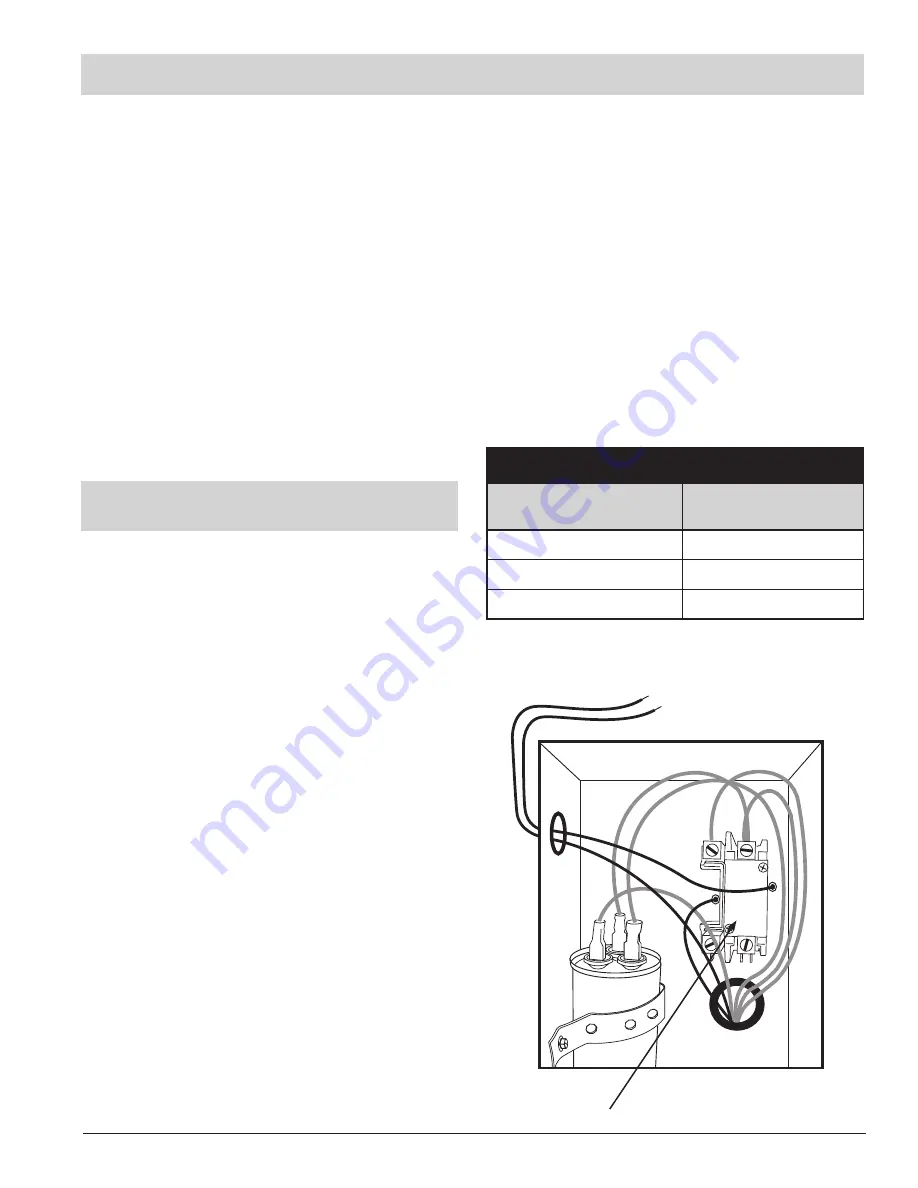

Electrical - Low Voltage

Low Voltage Maximum Wire Length

Table defines the maximum total length of low voltage wiring

from the condenser to the indoor unit and to the thermostat.

24 VOLTS

WIRE SIZE

MAX. WIRE

LENGTH

18 AWG

150 Ft.

16 AWG

225 Ft.

14 AWG

300 Ft.

Low Voltage Hook-up Diagram

Contactor

Field Wiring Low Voltage

Yellow

Red

Blue