Installation Guide for NCPE Split-System Condensing Units

29

1. Product Name

National Comfort Products

–

Thru the Wall Condensing Units

2. Manufacturer

National Comfort Products

539 Dunksferry Road, Bensalem, PA 19020

Phone: (800) 523-7138:

Fax: (215) 639-1674

Email:

Website:

www.NationalComfortProducts.com

3. Product Description

Thru the wall condensing units are designed for the

multi-family industry. The thru the wall operation saves

money and time with simple installation. No long refrigerant

or electrical runs, no ground clutter, no theft or vandalism,

no roof penetrations and the unit can be easily service

indoors.

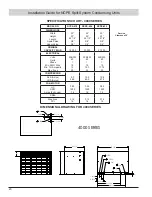

Models

1000 Series Condensing Unit – 12 SEER - 26 ¼" x 28 5/8" x 18 ½"

3000 Series Condensing Unit – 12 SEER – 24 1/8" x 32" x 18 ½"

3000 Series Heat Pump – 12 SEER – 24 1/8" x 32" x 18 ½"

4000 Series Condensing Unit – 12 SEER – 30" x 23" x 22 ½"

5000 Series Condensing Unit – 14 SEER – 39" x 27" x 18 ¼"

Capacities

1 ½ , 2 , & 2 ½ ton for condensing units

1 ½ & 2 ton for heat pumps

Materials

Cabinet to be constructed of Pre-Painted Galvanized Steel

Condenser coil shall be fabricated of raised lanced

aluminum fins mechanically bonded to seamless rifled

copper tubes.

Color –

Neutral tone finish of Tan

Voltage

Factory wired for 208-230 V, single phase, 60 Hz with low

voltage rated 24 V, 60 Hz Class 2 transformer not included

with condensing unit.

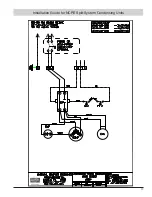

Service Valves

Brass with ability to check operating pressure with service

door reattached.

ENGINEERING SPECIFICATION GUIDE

4. Technical Data Limitations

All installations should factor a proper building heat gain,

along with appropriate duct sizing and electrical supply

wiring to be figured by a professional engineer familiar with

local and national codes.

5. Standard Controls & Components

Equipped to operate with a standard singles stage

thermostat (2 stage heat pump thermostats required for

3000 Series Heat Pumps only). All units equipped with high

efficiency scroll compressors and propeller style condenser

fan design.

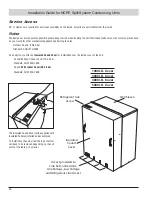

6. Install

Recommended installation with wall sleeve for clean finish

and future service accessibility. Provide minimum of 30”

in front of unit for service access and proper distances from

all outside utilities in accordance with all local and national

codes. A minimum vertical clearance of 48” between

units should be maintained to minimize recirculation of

condenser air.

7. Sales

National Comfort Products condensing units and matched

air handlers are dealt thru a variety of wholesalers. Contact

the factory to help locate a nearby distributor for price and

availability.

8. Warranty

2 year warranty of all parts and 5 year warranty of the

compressor. 90 days labor warranty.

9. Service

The units can be easily serviced from indoors and should

be properly maintained in accordance of the manufactures

instructions. All standard maintenance instructions are within

the installation guide.

10. Technical Support

Factory technical assistance is available to help with

any concerns or situations regarding National Comfort

Products.