Installation Guide for NCPE Split-System Condensing Units

7

Step 3:

Flux the copper tube and insert into the stub. Braze

the joint. No flux is necessary if a low to zero-silver

braze alloy is used.

Step 4:

After brazing, quench with a wet rag to cool the

joint and remove any flux residue. Evacuate,

purge or charge the connecting lines per the unit

manufacturer’s instructions.

Step 5:

This is not a back seating valve. To open the valve

remove the valve cap with an adjustable wrench.

Insert a 3/16” or 5/16” hex wrench into the stem.

Back out counter-clockwise until the valve stem just

touches the retaining ring.

Step 6:

Replace the valve cap finger tight then tighten an

additional 1/12 turn or 1/2 hex flat. A metal-to-metal

seal is now complete. Complete normal factory

recommended procedure

s.

1.

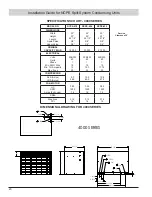

The unit has internally mounted service valves. Field tubing

may be routed through the locations provided in either the top or

rear flange. Care should be taken not to block access to internal

components. Seal unused knockouts with high grade sealant.

Gaskets are provided for liquid and suction lines.

Note: Always use refrigeration grade copper

tubing that is internally clean and dry for

refrigerant lines. Use clean hard drawn copper

tubing if no appreciable amount of bending is

necessary. If soft copper is used, avoid sharp

bends which may cause a restriction. Always

use heat sink materials during brazing to

prevent damage to service valves (See Page 6).

2.

Run refrigerant lines as directly as possible. Field piping

inside the condensing unit should not block access to major

components. Refrigerant lines should not be in direct contact

with the floor or ceiling joists. Use insulated or suspension type

hangers. When refrigerant lines run through a wall, seal openings

around the lines with a flexible material to avoid vibration to the

structure.

3

. Insulate the vapor line with a minimum 1/2

"

foam rubber

or other type insulation having an adequate vapor barrier. For

indoor units with a TXV, a liquid line filter drier must be installed

(SPORLAN #C-083-S or similar).

Caution: Dry nitrogen should always be supplied

through the tubing while it is being brazed,

as the high temperature required for brazing

will cause oxidation of the copper unless an

inert atmosphere is provided. The flow of dry

nitrogen should continue until the joints have

cooled. Always use a pressure regulator and

safety valve to ensure that only low pressure

nitrogen is introduced into the tubing. Only a

small flow is necessary to displace air and

prevent oxidation.

4.

When tubing installation is completed, seal openings around

tubing where tubing enters the unit cabinet.

5.

Standard refrigeration piping practices must be employed

when installing traps. When installing the condenser below the

evaporator, the suction line must be trapped with an inverted

trap the height of the evaporator coil. Consult the factory when

total equivalent length of refrigerant lines exceeds 50 ft.

6.

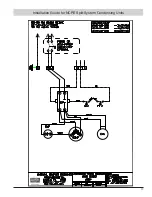

Install the refrigerant lines using the following procedure (See

Page 5).

a

. Remove the service port caps and Schrader Cores of the

liquid line service valve and the vapor line service valve of

the condensing unit. Connect low pressure dry nitrogen

to the liquid line valve service port.