Installation Guide for NCPE Split-System Condensing Units

25

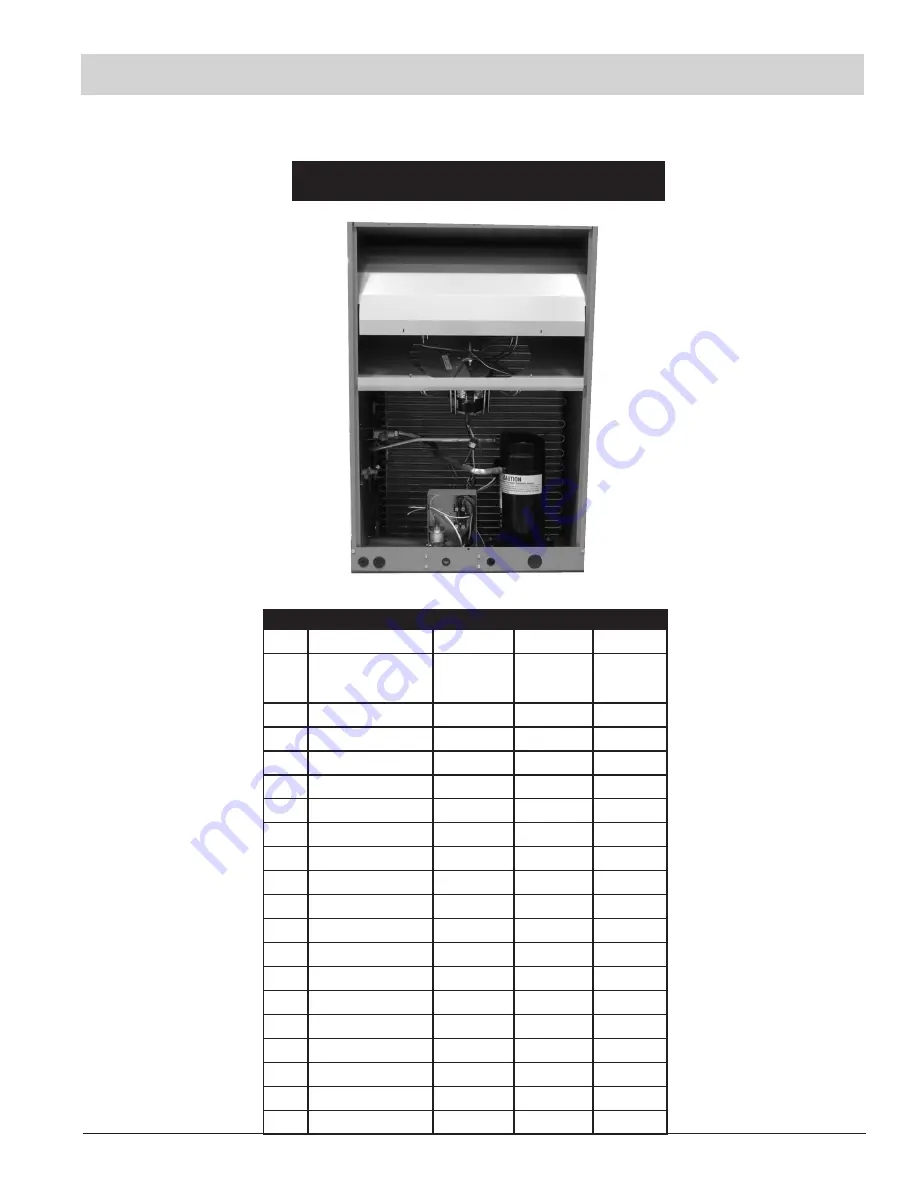

REPLACEMENT PARTS GUIDE

NCPE 5000 SERIES

ITEM

DESCRIPTION

NCPE-418

NCPE-424

NCPE-430

1

Contactor

14262082

14262082

14262082

2

Run Capacitor

14225391

30 mFd /

370V

14225393

40 mFd /

370V

14225392

35 mFd /

370V

3

Low Pressure Switch

14265026

14265026

14265026

4

High Pressure Switch

14265027

14265027

14265027

5

Compressor

14210241

14210239

14210244

6

Liquid Service Valve

14258603A

14258603A

14258603A

7

Vapor Service Valve

14258612

14258612

14258612

8

Condenser Coil

14208372

14208371

14208371

9

Motor

14270056

14270056

14270056

10

Prop Fan

14214038

14214038

14214038

11

Motor Mount

14270103

14270103

14270103

12

Access Panel

14256013

14256013

14256013

13

Patch Plate

14256008

14256008

14256008

14

Top Panel

14256225

14256225

14256225

15

Right Side Panel

14256222

14256222

14256222

16

Left Side Panel

14256012

14256012

14256012

17

Wire Grille

14269005

14269005

14269005

18

Radial Fan Mount

14256215

14256215

14256215

19

Touch Up Paint

14299630

14299630

14299630

20

Air Diffuser

14256223

14256223

14256223