Installation Guide for NCPE Split-System Condensing Units

13

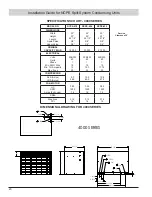

Air Flow Chart

1000, 3000, & 4000 Series

Model

Air Handler

Tap

CFM

Static

NCPE-418

NCPAH-24-A

2

580

0.1

NCPE-418

B6VMMX24

6, 8

650

0.1

NCPE-424

NCPAH-24-A

5

830

0.1

NCPE-424

B6VMMX24

5, 7, 8

850

0.1

NCPE-430

NCPAH-36-A

1

950

0.1

NCPE-430

B6VMMX36

1, 5, 6

950

0.1

Air Flow Chart

5000 Series

Model

Air Handler

Tap

CFM

Static

NCPE-418 NCPAH-24-A

2

580

0.1

NCPE-424 NCPAH-24-A

5

820

0.1

NCPE-430 NCPAH-36-A

1

950

0.15

NCPE-418 NCPAH-24-M

1

620

0.1

NCPE-424 NCPAH-24-M

4

860

0.1

NCPE-430 NCPAH-36-M

2

1045

0.15

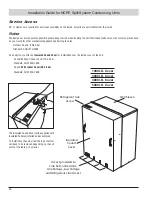

Maintenance

1.

Annually clean the inside of the unit to keep the weep holes

in the base pan and in the fan scrolls open to assure proper

drainage of water from the unit.

2.

Keep the condenser coil clean and free of anything that

restricts free air flow. On sea coast applications the condenser

coil should be washed periodically to remove salt accumulation.

3.

Reduced indoor air flow through a duct system will cause

indoor coil to ice up in cooling. If this condition is allowed to

continue, premature system failure will result. Indoor air filters

should be cleaned and changed regularly.

4.

Annually check units mounting to structure to ensure

integrity. Seal between cabinet and/or sleeve for air or water

leakage. Check exposed surfaces for corrosion. Replace or paint

part as required. This maintenance is critical to prevent stains

and damage to exterior surface of building.

5.

Inspect refrigerant piping for leaks and suction line insulation.

Improper insulation can cause condensate water damage.

6.

Pressure and temperature readings of high and low side

of system should be checked for proper super heat and/or

subcooling. Correct if required.

7.

Inspect motor mount, amps to nameplate, hubs for tightness,

balance, and rust or corrosion.

8.

Inspect wire connection for evidence of arcing, overheating

and deterioration

Checkout Procedures and

Troubleshooting

CHECKOUT PROCEDURE

After installation has been completed, it is recommended

that the system be checked against the following list:

1. Leak check refrigerant lines.

2. Properly insulate suction lines and

fittings.

3. Properly secure and isolate all

refrigerant lines.

4. Seal passages through masonry.

If mortar is used, prevent mortar

from coming into direct contact with

copper tubing.

5. Verify that all electrical connections

are tight.

6. Observe outdoor fan during on cycle

for clearance and smooth operation.

7. Be sure that indoor line drains freely.

Pour water into drain pan.

8. Be sure that supply registers

and return grilles are open and

unobstructed.

9. Be sure that a return air filter is

installed.

10. Be sure that the correct airflow

setting is used. (Indoor blower motor)

11. Operate complete system in each

mode to ensure safe operation.