2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor

5.5

Reassembly

1612LSC Speed Increaser Type

5-45

5.5.2 Bearing Head and Main Rotor Casing

Since the bearing head gasket

[12]

is not formed symmetric laterally, pay

attention to the installation direction.

If you place the bearing head gasket by just hanging it on the stud bolts, the gasket

will protrude into the inside of the rotor casing when the casing is assembled. Apply

sufficient amount of oil, etc. to the gasket to make it fully attached to the surface to

prevent protruding upon the assembly.

a) In case of assembling the low-stage, fit the unloader push rod [67] in the hole of bearing head [11-1].

Then, slide the bearing head or main rotor casing to let them mate together.

b) Loosely tighten the two screws, secure the alignment pin [3-1] in position, and then tighten the

screws in turn evenly.

c) After tightening the screws, check that the bearing head gasket is not protruding inside the casing.

d)

Also, move the slide valve back and forth to check that it works normally.

Make sure to check for protrusion of the bearing head gasket after assembling the

bearing head and rotor casing. If this work is not performed, measurements may be

incorrect due to the gasket becoming stuck between the end of the rotor and the

surface of the bearing head when adjusting end clearance. Also, performance may

deteriorate by operating the compressor after confirming the incorrect end

clearance.

e) Since the full height of the high-stage main rotor casing is lower than that of the bearing head, both

centers will not be aligned when they are placed on the work bench. Therefore, either use a

pedestal as used in the disassembly process or lift the rotor casing using a crane or other device to

align the centers.

The assembly procedure after mating the both casing flanges is same as the high-stage.

f)

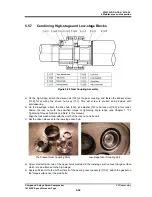

As shown in the right picture, make

sure to attach the O-ring [197] and

O-ring gland [326] to the part where

the unloader push rod goes through

low-stage bearing head.

However, this O-ring gland [326] is

applied after the design modification

in July 1986. For the compressors

manufactured before this change

O-ring [197] should be attached in

the groove on bearing head.