2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor

5.4 Disassembly and Inspection

1612LSC Speed Increaser Type

5-39

5.4.16 High-stage

Bearing

Head and Main Bearings

There is a gas discharge port, based on the compressor’s operating conditions, on the surface that has

the rotor of the bearing head [11-2] assembled on it.

This discharge port affects the performance of the compressor.

On the bearing head there is also the main bearing which supports one end of the rotor.

5.4.16.1 Disassembly

a) Remove all hexagon socket head cap screws [2-2] that hold the casing and bearing head and hit

alignment pins into the rotor casing side.

b) Screw two hexagon head cap screws [2-2] into the

jacking threaded holes of the main rotor casing flange to

push the bearing head evenly.

c)

When some gap is observed, use a scraper to remove

one side of the gasket [12-2] from the body.

d) By using internal snap ring pliers, remove the snap ring

[29-2] that is retaining the main bearing.

e)

The main bearing [27-2] is lightly press fit to the bearing

head.

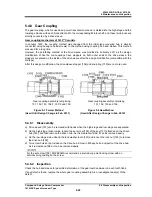

As shown in the right picture, screw two M8 eyebolts into

threaded holes on the main bearing, and pull out it.

5.4.16.2 Inspection

a) We recommend as well as the side bearings, unconditional exchange of the main bearings on the

occasion of the compressor overhaul, but for confirmation of the compressor condition and system

operating condition, carefully check the sliding part metal surface of the main bearings.

If the metal surface is gray or any foreign matter is buried, also carefully check the wear of the rotor

shaft.

b) Check the condition of the surface of the bearing head on the rotor side, where the discharge port is.

Properly mend the surface if any flaw is observed. If the entire surface has significant flaws, either

the thrust bearing is defective or the end clearance adjustment is poor.

If oil compression has been caused during the operation, carefully and thoroughly check the area of

the discharge port in particular. If the continued use is in doubt at all, perform the penetrant testing

(color check) to determine if it can be used or not.