- 40 -

Problem

Cause Remedy

5. The 2nd-stage limit

switch operates.

(1) Incorrect connection of power supply line

(2) Wire rope wound reversely

(1) Exchange the phases R and T

of the power supply.

(3) Although the use of the no-load high-speed

function has been specified, the upper limit stop

point has not been set. Or the upper limit set

position is too high.

(2) Set the upper limit correctly.

(3) Set the upper limit to the

proper position.

6. Wire rope is cut.

(1) The rope catches on something during hoisting.

(2) Corrosion due to chemicals

(3) Use of badly worn wire rope

(1) Handle and maintain the rope

properly. Replace the

defective wire rope.

(Use the Mitsubishi genuine

wire rope.)

7. The hoist does not

start even if the

pushbutton is

pressed.

(1) Pushbutton defective, or pushbutton cable

broken

(1) Repair, replace, or cut out.

(2) Incorrect wiring of power switch, fuse, contactor,

or pushbutton, imperfect contact of trolley line,

loose screws, etc.

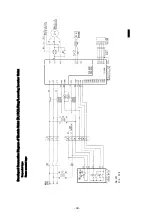

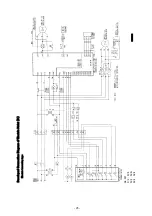

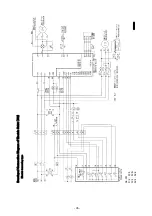

(2) Check, and repair. See the

expanded connection diagram.

(3) The inverter does not give 3-phase output.

(3) Check the inverter.

(4) No signal is returned from the sensor, or one of

the rotation signals (signals for 2 phases) is not

returned from the RRS board.

(4) Check and replace the RRS

board. Check the signal line

(microphone cord) for dis-

connection.

(5) The hoisting motor torque is insufficient for

overload, and the hoist stops.

(5) Reduce the load.

(6) The hoisting motor overheats due to too frequent

use, the torque drops, and the hoist stops.

(6) Use the hoist at appropriate

intervals.

8. The hoist lowers and

stops during hoisting

(1) Overload

(1) Reduce the load.

(2) Hoisting motor overheat

(2) Use the hoist at appropriate

intervals.

(3) Hoisting motor wire breakage

(3) Check, and repair.

9. The hoist stops

suddenly during

hoisting.

(1) Inverter trip due to overvoltage caused by

hoisting an overload.

(1) Reduce the load.

(2) Inverter overvoltage tripping is caused due to rise

in the resistance value that is caused by

temperature rise of the discharging resistor due to

too frequent use.

(2) Use the hoist at appropriate

intervals.

(3) Disconnection of discharging resistor

(3) Check, and repair.

10. Power is applied to

the traversing motor,

but the motor growls

and takes a longer

time (2 sec. or more)

to start.

(1) Electric resistance is high due to wiring, switch

or trolley contact failure or loosened screws.

(Voltage drop at start)

(1) Check, and repair.

(2) Wires too thin or long

(2) Change the wiring in accord-

ance with the selection table.

(3) Supply voltage too low.

(3) Change the transformer taps.

(4) Electromagnetic brake not released.

(4) See Item 14.

(5) Defective electromagnetic brake coil.

(5) Replace the coil.

11. The hoist suddenly

stops during lifting

or lowering

operation.

(1) The 1st-stage limit switch functions.

(1) Lower the load.

(2) Inverter trip due to too low supply voltage

(2) Change the transformer taps.

(3) Hoisting brake works.

(3) See Item 14.

(4) Inverter trip due to overload or ground lifting

(4) Re-examine the lowering

method and load.

(5) Fall caused by overload is detected.

(5) Re-examine the lowering

method and load.

(6) Malfunction due to noise.

(6) Fit a noise filter to the 3-phase

power supply.

Содержание UM 10t

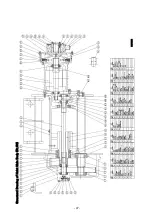

Страница 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

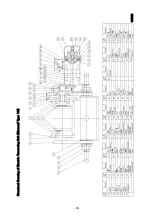

Страница 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

Страница 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

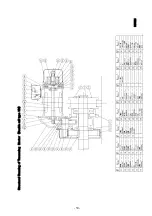

Страница 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

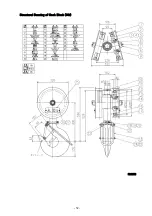

Страница 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Страница 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...

Страница 60: ...MITSUBISHI ELECTRIC FA INDUSTRIAL PRODUCTS CORPORATION Specifications subject to change without notice ...