- 39 -

General Troubleshooting

If the hoist has been used under unfavorable working condition, handled roughly or become old,

like general machines, it shows various troubles and nonconformities.

All troubles and nonconformities cannot be described here. General troubles are listed below for

your reference.

Most of troubles not listed below are caused special factors. Regarding such troubles, consult

the nearest distributor or Mitsubishi Electric Hoist Corporation.

General troubleshooting

Problem Cause

Remedy

1. Touching the hoist or

pushbutton pendant

causes an electric

shock.

(1) I-beam or pushbutton pendant metallic casing

grounding failure

(1) Ground completely.

100

Ω

or less at 200 V

(2) Adhesion of paint to the I-beam surface

(2) Use the hoist suitable for the

ambient conditions

(waterproof type, etc.).

Remove paint completely.

Leakage current increases due to high-frequency

component of inverter output voltage. The

rated sensitivity current of the earth-leakage

circuit breaker shall be 100 mA or more to

prevent unnecessary operations.

The circuit breaker is designed nor for

prevention of electrical shocks, but for

prevention of a fire caused by electrical leakage.

For this reason, remedies (1), (2), and (5)

described on the right side should be observed.

(3) Hoist or pushbutton pendant insulation failure

(3) Check, and repair.

(4) Current leaking from other equipment or wiring

reaches the hoist through the I-beam.

(4) Check, and repair.

(5) The floor conductivity is high.

•

The floor is wet with a highly conductive liquid,

such as water.

•

The hoist is on a highly conductive surface, such

as an iron plate, steel structure and surface plate.

(5) Install the hoist on a floor

with low conductivity, such as

a dry concrete floor.

2. Operation in reverse

direction to that

indicated on

pushbutton.

(1) Incorrect connection of power supply line

(1) Exchange the phases R and T

of the power supply.

(If the commercial power is used for traversing

operation)

Even if the power line is not connected correctly,

operation will not be performed in the opposite

direction.

(2) Wire rope wound reversely.

(2) Wind the rope correctly.

3. Wire rope wears

badly.

(1) The rope wears soon because it is frequently

pulled laterally and vertically.

(1) Correct the using method.

(2) Disordered winding

(2) See Item 4.

(3) Use of wire rope other than parallel stranded rope (3) Replace the wire rope with a

proper one.

(4) Wire rope oil not applied.

(4) Apply oil.

4. Wire rope is wound

ununiformly.

(1) Pulling laterally and vertically at too large angles

(Less than 10

°

for pulling laterally or less than 3

°

for pulling vertically)

(1) Correct the using method.

(2) Wire rope distorted

(2) Replace.

Содержание UM 10t

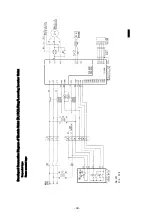

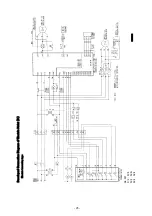

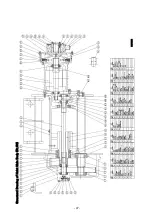

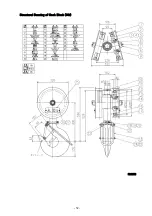

Страница 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

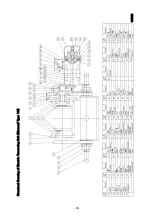

Страница 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

Страница 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

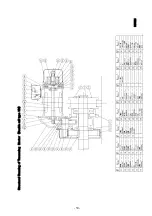

Страница 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

Страница 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Страница 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...

Страница 60: ...MITSUBISHI ELECTRIC FA INDUSTRIAL PRODUCTS CORPORATION Specifications subject to change without notice ...