- 35 -

Classes B and C

No.

Check item

Description

Month

Acceptability

Problem

and remedy

Date of

completion

of repair

1

Check the pushbuttons for damage.

Check the inside and contacts.

2

Electro-

magnetic

brake

electro-

magnet

Check the screws for looseness.

Check the parts for wear and damage.

Check that the gap between the cores is

proper.

Check that the lining thickness is

proper.

Check that no pins have dropped.

Open the cover, and check.

Lubricate the sliding and revolving

parts.

Replace the brake disks with new ones.

3

Check that the diode (in the control box) for the

hoisting brake and the diode for the traversing

operation are not damaged. Also check that their

lead wires are not disconnected.

Open the cover to check the diodes.

4

Check the pushbutton pendant cable and power

cable for external flaws. Check the messenger

and hanging wire for damage. Check the hanger

for disconnection.

Check the leading-out ports.

Check the wire for sagging.

5

Check that the wire rope has been lubricated.

If the wire rope is dry, apply wire rope

oil.

6

Check the electromagnetic contactor, contacts,

insulated parts and mechanical parts for damage

and wear. Check the screws for looseness.

Check visually.

Check that all the screws are tightened

firmly.

7

Check the overwinding limit switch and contacts

for wear. Check the clamping screws for

looseness.

Check that the switch and the contacts

are tightened properly.

Check that the switch and the contacts

operate properly.

8

Check the trolley wire for looseness and rust.

Check the wires.

9

Check the current collector for contact failure and

wear.

Check the rotation. Check the wire

connections for looseness.

Check the spring force.

10

Check the traversing wheels and guide rollers for

wear.

Wear must be less than 5% of the

diameter and less than 50% of the

flange thickness.

11

Check the traversing brake for attraction, release

and coasting condition.

12

Check the rail for abnormal wear, loosened

seams, external flaws and cracks. Check the

clearance between the rail and the guide roller or

the wheel flange.

Wear less than 5% in width and less

than 10% in thickness is allowed.

Clearance between the rail and the

guide roller or the wheel flange less

than the specified value is acceptable.

(Refer to “Installation on I-Beam”.)

13

Check the hoisting brake resistor for damage.

Check visually.

14

Check the bolts for looseness.

Check visually. Tighten the bolts

again.

The rules prescribe to prepare a monthly inspection sheet based on these items and store the

results for three (3) years.

Items to be checked every 3 or 6 months and to be regarded as important

items from the viewpoint of safety.

Frequently used parts shall be checked every one to three months.

Содержание UM 10t

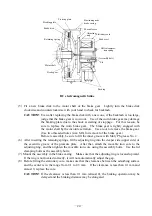

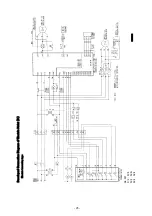

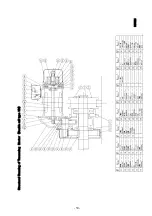

Страница 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

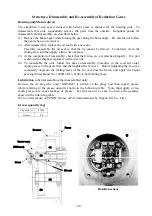

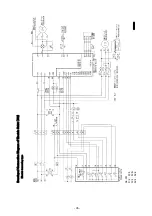

Страница 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

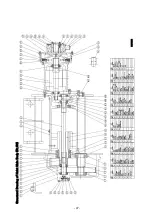

Страница 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

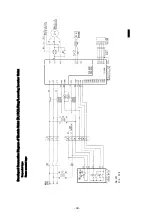

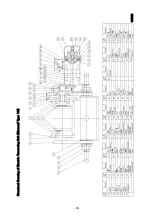

Страница 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

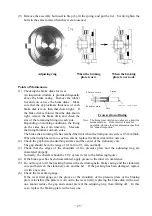

Страница 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Страница 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...

Страница 60: ...MITSUBISHI ELECTRIC FA INDUSTRIAL PRODUCTS CORPORATION Specifications subject to change without notice ...