- 33 -

Monthly Inspection

The person responsible for maintenance of hoist shall check the following items directly touching

the hoist, and repair defective parts.

The time of inspection of each part shall be determined depending on importance from the

viewpoint of safety, difficulty in maintenance, frequency of uses, and wearability. The parts are

classified as shown below.

Class A

No. Check

item

Description

Month

Acceptability

Problem

and remedy

Date of

completion

of repair

1

Check that there are no obstacles within the

traversing range.

Check that the load will not hit

against other articles.

2

Check the stoppers on both the ends of rail

for deformation and missing, and check the

mounting bolts for looseness.

3

Check the ground lead of the pushbutton

pendant metallic casing for breakage,

check the screws for looseness, and check

the pushbutton cable through holes for

abnormalities.

If the metallic casing leaks, an

electrical shock can occur. Look

over the inside.

4

State of the operation buttons

Check that the interlocks are complete.

Check that the buttons return to

position smoothly.

5

Check the operation of the overwinding

limit switch lever.

If the pin has been dropped, the

switch lever will not function.

Check that the lever functions cor-

rectly. Check that the lever has

been properly adjusted.

6

Wire

rope

Check the strands for breakage.

Less than 10% of number of

strands in one twisted wire

Check for wear.

7% or less of the nominal diameter

Check for kink, deformation, and

corrosion.

Kink, deformation, and corrosion

should not be allowed.

Check the frame fixing parts, pins,

and sheaves.

Stoppers, split pins, wear

Check the terminal fitting inlet for

corrosion.

Insufficient lubrication, breakage,

and corrosion on the root of the

rope

7

Hook

block

Check that the thrust ball bearing

rotates smoothly.

Check that the nut stopper is not

damaged.

Check that the foot nut is

provided with loosening

preventive means.

Check the split pin and setscrew for

missing.

Check the sheave for damage.

Check for flaws and wear of the

groove.

Check the sheave case and key

plate (nameplate) for damage and

looseness. Check the slinging

wire latch.

Check the clamping screws for

looseness and damage.

Check for backlash and spring

effect.

Items to be surely checked every month and to be regarded as important items from

the viewpoint of safety.

Содержание UM 10t

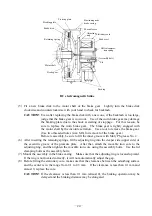

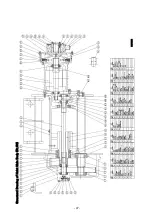

Страница 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

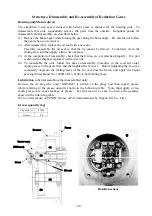

Страница 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

Страница 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

Страница 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

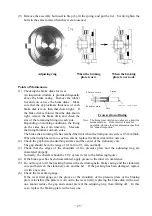

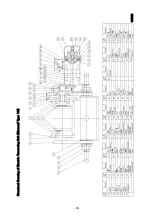

Страница 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Страница 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...

Страница 60: ...MITSUBISHI ELECTRIC FA INDUSTRIAL PRODUCTS CORPORATION Specifications subject to change without notice ...