- 31 -

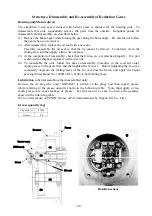

Maintenance and Inspection

Hoist check items are described in details below. Crane Safety Code (Clauses 34, 35 and 36)

prescribes to carry out daily inspection and periodic self-imposed inspection. Be sure to carry

out the maintenance and inspection.

Daily Inspection of Hoist

Before starting the daily work, the person responsible shall operate the hoist without load, and

check the following points.

No.

Daily inspection item

Description

1

Check the hoist operator working range for obstacles.

Ensure safety in the working area.

2

Look over the traversing rail on the floor to check for

abnormalities.

Check also the stoppers.

3

Check that the limit switches function correctly.

If pushbuttons are not wired correctly, the limit switches

may not be effective.

After releasing your finger from a pushbutton, check

that the hook block traveling distance is within 20 to 50

mm. If the traveling distance is in this range, the hoist

can perform operation properly.

Also check the operation and the time required for

starting. If it takes 1 second or more to start the

operation, or if operation is not smoothly performed,

judge that the hoist is defective.

4

Check for strange noise, odor and vibration.

5

Check whether the brake is effective.

(For Type UR, check whether the immediate

stoppage is possible during high-speed lifting

operation.)

6

Check that the

hoist smoothly

moves as

directed by the

pushbuttons.

●

Check that the hoist moves

correctly at low and high speeds.

●

Check that the speed can be

switched smoothly between low

and high speeds without

abnormalities.

●

Check that the hoist stops after

decelerating. Check that the

distance required to stop is uniform

as usual.

The time required for acceleration to the high speed (60 Hz)

should be 1 second, and the time required for deceleration

from the high speed (60 Hz) to stoppage should be 0.5

seconds. After releasing the pushbutton switch, if the hook

block traveling distance is in the range of 50 to 80 mm, judge

that there is no problem.

7

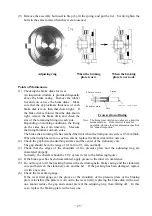

Check that the hook block sheave rotates smoothly.

Check that the hook rotates easily, and that the hook nut

has been secured normally. Check that the wire rope

cannot come off the sheave.

Prevention of drop of load

8

Check that the wire rope has been properly wounded on

the drum.

Improper winding will result in reduction in service life and

wire breakage.

9

Check the slinging tools for defects.

10

Check the whole body for abnormal overheat and color

change.

Содержание UM 10t

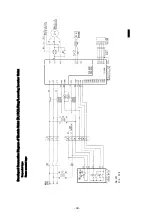

Страница 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

Страница 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

Страница 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

Страница 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

Страница 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Страница 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...

Страница 60: ...MITSUBISHI ELECTRIC FA INDUSTRIAL PRODUCTS CORPORATION Specifications subject to change without notice ...