-

22

-

Error Detection Function

If an error is detected, the 7-segment LED indicator will flash the error number, and the hoist will

be stopped. In this case, release the pushbutton switch, and then press it again, or stop supplying

the electric power, eliminate the cause of the error, and then restart operation.

List of lifting/lowering errors

Error

Description of error

Measures Cause

Restarting

Display

Power failure

The AC power is turned off.

Immediate stoppage

Error indication

Power failure

Imperfect contact of

trolley

Possible

Er01

Power supply

voltage too low

The voltage of the PN line is

460 V or less.

Immediate stoppage

Error indication

Power supply capacity

shortage

Imperfect contact caused

in trolley line

Possible

Er02

Defective

pushbutton

Both the lifting and lowering

commands are input at the

same time.

The pushbutton signal input

circuit is defective.

Deceleration and

stoppage

Error indication

Wiring error

Defective CPU board

Possible

Er11

Starting error

During lifting/lowering

operation, the 2-phase signal

sent from the rotation sensor

cannot be received for 0.5

sec or more.

Deceleration and

stoppage

Error indication

Overloaded during lifting

operation (Note 4)

Defective hoisting brake

Defective inverter

Possible

Er12

Regenerative

voltage too high

The voltage of the PN line is

760 V or more.

Immediate stoppage

Error indication

Overloaded during

lowering operation

(Defective regenerative

circuit)

Possible

Er13

Lowered during

lifting operation

During lifting operation or

stoppage of operation, the

hook is lowered.

Immediate stoppage

Error indication

Defective hoisting brake

Defective inverter

Possible

Er14

Overwork

Overcurrent

Control power

supply error

The “Fout” signal is output.

(Overcurrent or overheat)

Immediate stoppage

Error indication

Overwork

Overload (Note 4)

Defective IPM

Possible

(Note 2)

Er16

(Note 1)

Defective rotation

sensor

One of 2 signals is missing.

Deceleration and

stoppage

Error indication

Disconnection

Defective rotation sensor

Inhibited

Er21

Over-speed

The speed is higher than the

maximum speed 110%.

Immediate stoppage

Error indication

Motor line disconnection

Defective inverter

Inhibited

Er22

(Note 1)

Limit position

overrun

Counter overflow

Deceleration and

stoppage

Error indication

Noise

Defective rotation sensor

Defective CPU board

Inhibited

Er23

Overload

(Note 3)

The applied load is more

than the judgment value.

Deceleration and

stoppage

Overload

Possible

oL

Note 1: Set the electronic operation limit position again.

Note 2: If the hoist is stopped due to overheat, restarting the hoist will not possible until the power module is cooled enough.

Note 3: This error will not be recorded in the error history.

Note 4: This error may occur if the overload stoppage function is not used or if an extremely large load is applied, e.g. earth lifting

is performed.

Содержание UM 10t

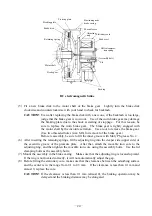

Страница 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

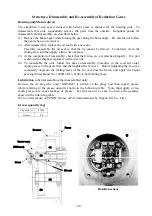

Страница 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

Страница 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

Страница 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

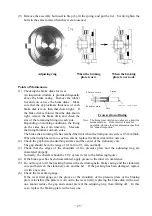

Страница 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Страница 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...

Страница 60: ...MITSUBISHI ELECTRIC FA INDUSTRIAL PRODUCTS CORPORATION Specifications subject to change without notice ...