8

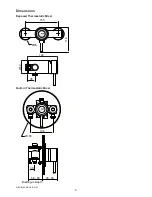

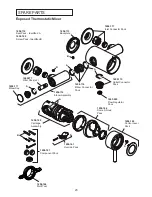

Exposed Thermostatic Mixer

Installing the Thermostatic Mixer

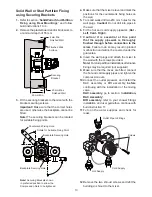

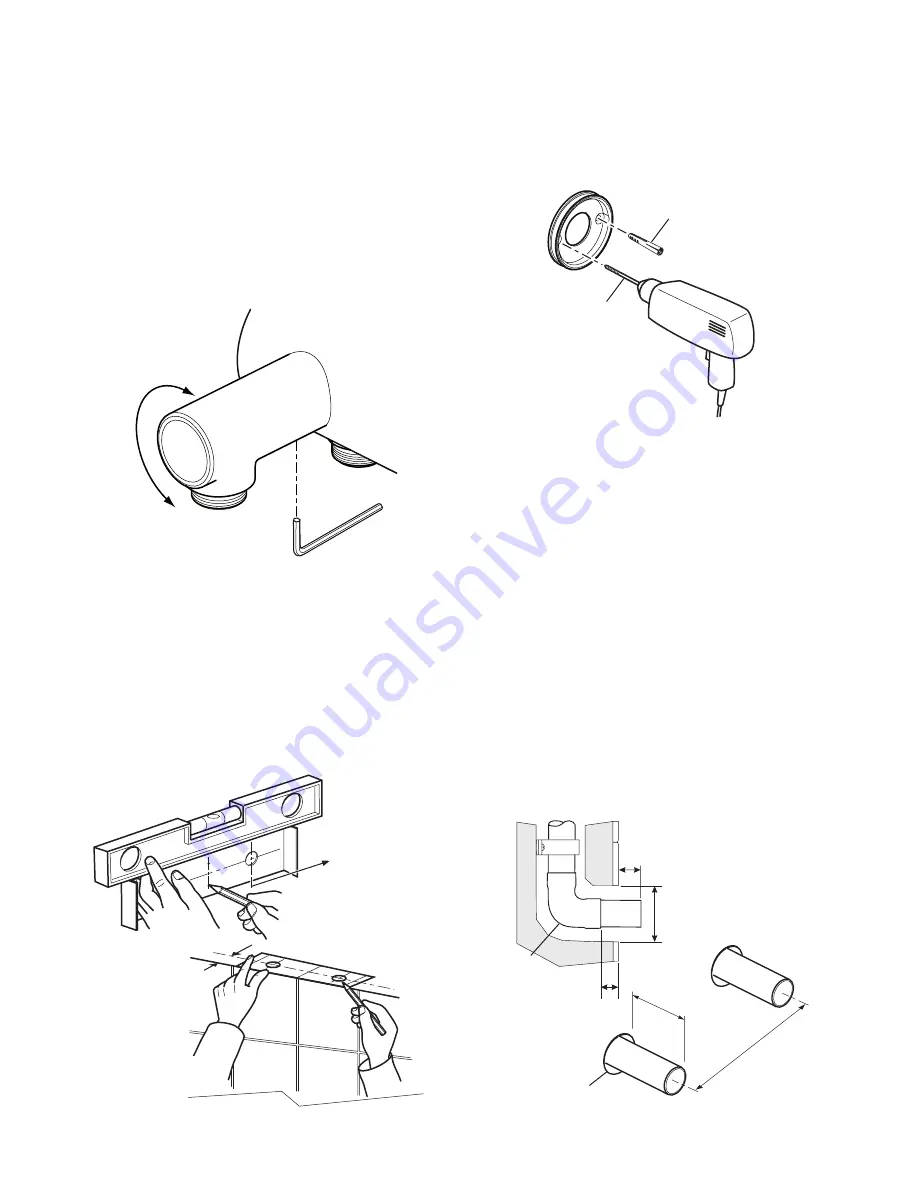

1.

The thermostatic mixer can be installed with

rear, rising or falling supply inlets. Decide

on the most appropriate method for your

installation and if necessary, loosen the

grubscrews and rotate the inlet elbows to

suit.

Important!

Make sure that the elbows are

pushed fully onto the mixer before tightening

the grubscrews,

do not

overtighten.

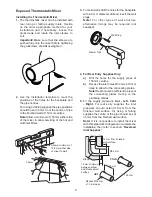

2.

Use the installation template to mark the

positions of the holes for the backplate and

the pipe centres.

For rising or falling supplies the pipe positions

should be set 35 mm from the centre of pipe

to the finished wall at 153 mm centres.

Note!

Allow a minimum of 150 mm either side

of the mixer to allow servicing of the hot and

cold inlet filters.

Allow a minimum of

150 mm either side

of mixer to wall

35 mm

3.

For solid walls drill the holes for the backplate

with a 6 mm diameter drill and insert the wall

plugs.

Note!

For other types of wall structure

alternative fixings may be required (not

supplied).

Wall Plug

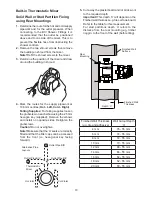

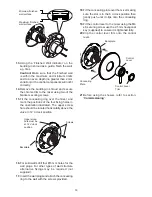

4. For Rear Entry Supplies Only:

a)

Drill the holes for the supply pipes at

153 mm centres.

b)

Recess the inlet holes Ø32 mm x 10 mm

deep to allow for the concealing plates.

Note!

Depth must be sufficient to prevent

the concealing plates fouling on the

plumbing elbows.

5.

Fit the supply pipework:

Hot - Left, Cold

- Right.

For rear entry supplies the inlet

pipework should extend 18 mm from the

finished wall surface, for rising or falling

supplies the centre of the pipe should be set

35 mm from the finished wall surface.

Note!

If it is not possible to install the mixer

with this pipework configuration complete the

installation then refer to section:

‘Reversed

Inlet Supplies’

.

Ø6 mm Drill

10 mm minimum

between elbow

and finished wall

surface

Ø32 mm

18 mm from finished

wall surface

Elbow

Recess Ø32 mm

x 10 mm deep

18 mm

153 mm

HOT

COLD

Содержание Element SLT

Страница 27: ...27 NOTES...