20

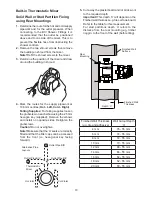

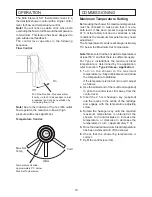

It is a requirement that all TMV2 approved

valves shall be verified against the original

set temperature results once a year. When

commissioning/testing is due the following

performance checks shall be carried out.

Measure the mixed water temperature at the

outlet.

Carry out the cold water supply isolation test by

isolating the cold water to the TMV, wait for five

seconds if water is still flowing check that the

temperature is below 46°C.

If there is no significant change to the set outlet

temperature (±2°C or less change from the

original settings) and the fail-safe shut off is

functioning, then the valve is working correctly

and no further service work is required.

Notes!

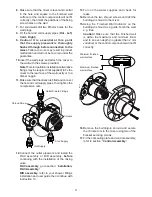

If there is a residual flow during the

commissioning of the valve or the annual

verification (cold water supply isolation test), then

this is acceptable providing the temperature of

the water seeping from the valve is no more than

2°C above the designated maximum mixed water

outlet temperature setting of the valve.

Temperature readings should be taken at the

normal flow rate after allowing for the system to

stabilise.

The sensing part of the thermometer probe

must be fully submerged in the water that is to

be tested.

Any TMV that has been adjusted or serviced must

be re-commissioned and re-tested in accordance

with the instructions given in this guide.

The installation of thermostatic mixing valves must

comply with the requirements of the Water Supply

(Water Fittings) Regulations 1999.

FAULT DIAGNOSIS

If you require a Mira trained service engineer or

agent, refer to section:

‘Customer Services’

.

Fault Diagnosis

Symptom:

• Only hot or cold water from the mixer outlet.

• Outlet temperature too hot / too cold.

Cause / Rectification:

• Inlets reversed (hot supply to cold supply).

• No hot water reaching mixer.

• Check the filters for any blockage.

• Installation conditions outside operating

parameters, refer to sections:

‘Specifications’

and

‘Commissioning’

.

—————————————

Symptom:

• Fluctuating or reduced flow rate.

Cause / Rectification:

• Check the showerhead, hose and filters for

any blockage and clean.

• Make sure that the maintained inlet pressures

are nominally balanced and sufficient, refer to

section:

‘Specifications’

.

• Make sure that the inlet temperature

differentials are sufficient, refer to section:

‘Specifications’

.

• Flow regulator fitted incorrectly.

• Air lock or partial blockage in the pipework.

—————————————

Symptom:

• Water leaking from showerhead.

Cause / Rectification:

• Normal for a short period after shut off.

• Check that the pressures are not in excess of

the specifications for the product.

• Renew the thermostatic cartridge.

Содержание Element SLT

Страница 27: ...27 NOTES...