10

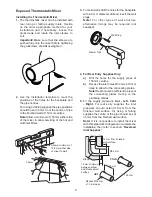

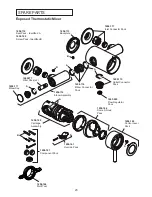

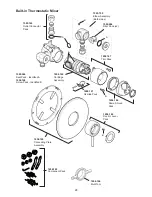

Built-in Thermostatic Mixer

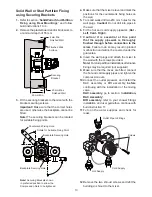

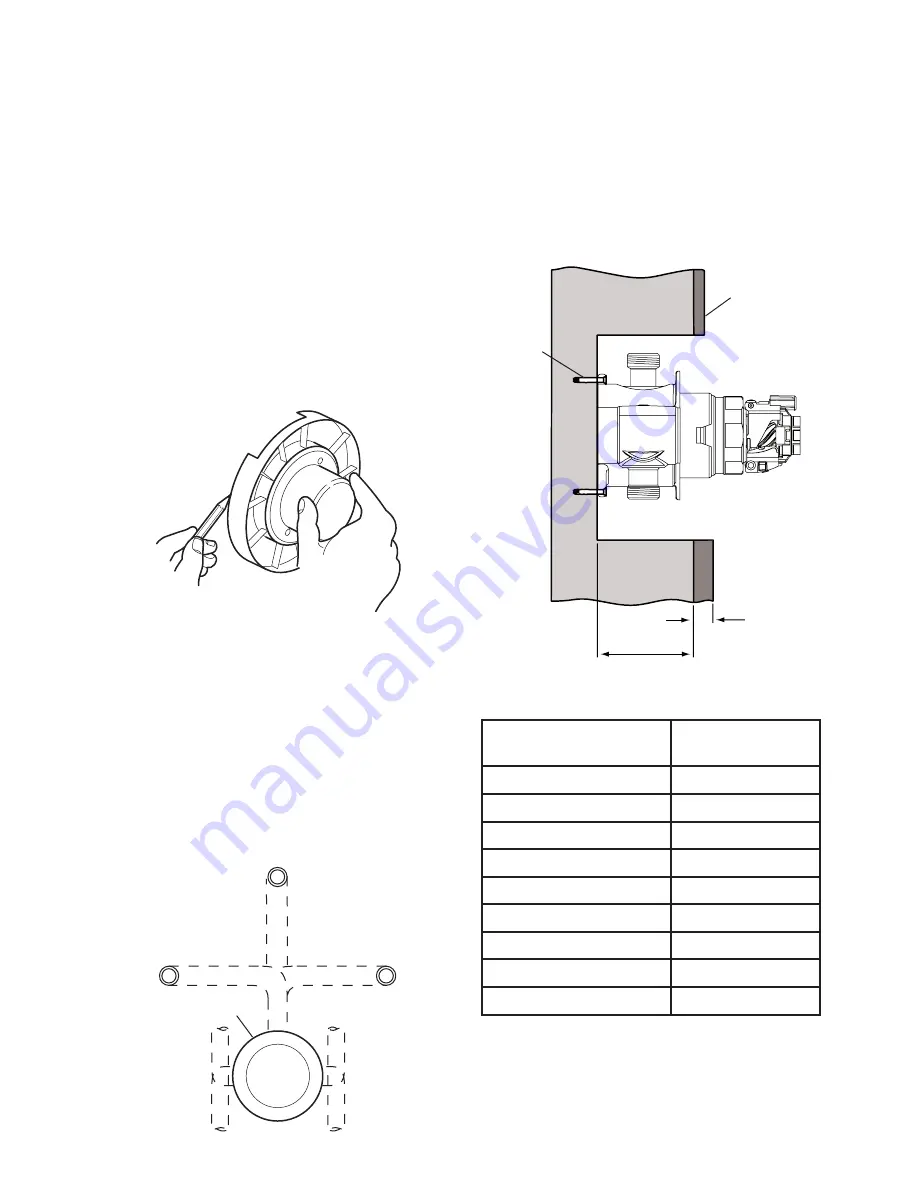

Solid Wall or Stud Partition Fixing

using Rear Mountings

1.

Determine the route for the hot and cold supply

pipework and for the outlet pipework. When

connecting to the BIV Shower Fittings it is

recommended that the outlet be positioned

above and to one side of the mixer. This is to

prevent the flexible hose from obstructing the

shower controls.

2.

Remove the two shroud screws then remove

the building-in shroud from the mixer.

Note!

Refit the shroud screws to the mixer.

3.

Determine the position of the mixer and draw

around the building-in shroud.

4.

Mark the routes for the supply pipework at

108 mm centres (

Hot - Left, Cold - Right

).

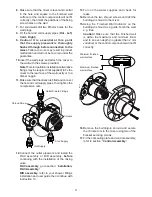

Falling Supplies:

For falling supplies loosen

the grubscrew on each elbow using the 2.5 mm

hexagon key (supplied). Remove the elbows

and install on opposite sides. Retighten the

grubscrews.

Caution!

Do not overtighten.

Note!

Make sure that the ‘O’ seals are correctly

fitted and that the filter caps can be accessed

from the front (i.e. hexagonal key facing

forward).

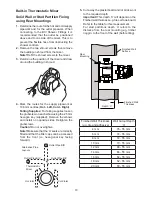

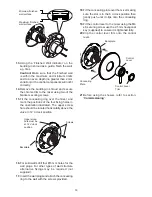

Finished Wall

Surface

Finished Wall

Thickness

Depth ‘X’

Rear

Mounting

Finished Wall Thickness

(e.g. tile and adhesive)

Wall Cutout Depth

‘X’

4 mm

76 - 55 mm

6 mm

74 - 55 mm

8 mm

72 - 55 mm

10 mm

70 - 55 mm

12 mm

68 - 55 mm

14 mm

66 - 55 mm

16 mm

64 - 55 mm

18 mm

62 - 55 mm

20 mm

60 - 55 mm

5.

Cut away the plasterboard and/or brick work

to the required depth.

Important!

This depth ‘X’ will depend on the

finished wall thickness e.g. tiles or facia board.

Refer to the table for this measurement.

For stud partitions depth ‘X’ refers to the

distance from the rear mounting e.g. timber

noggin, to the front of the wall (before tiling).

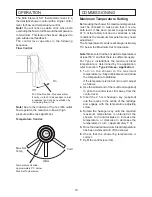

Outlet Pipe BIR

Outlet Pipe BIV

Outlet Pipe BIV

Cold Inlet

Hot Inlet

Thermostatic

Mixer

Alternative Pipe

Layouts

Содержание Element SLT

Страница 27: ...27 NOTES...