3-2

List of Functions

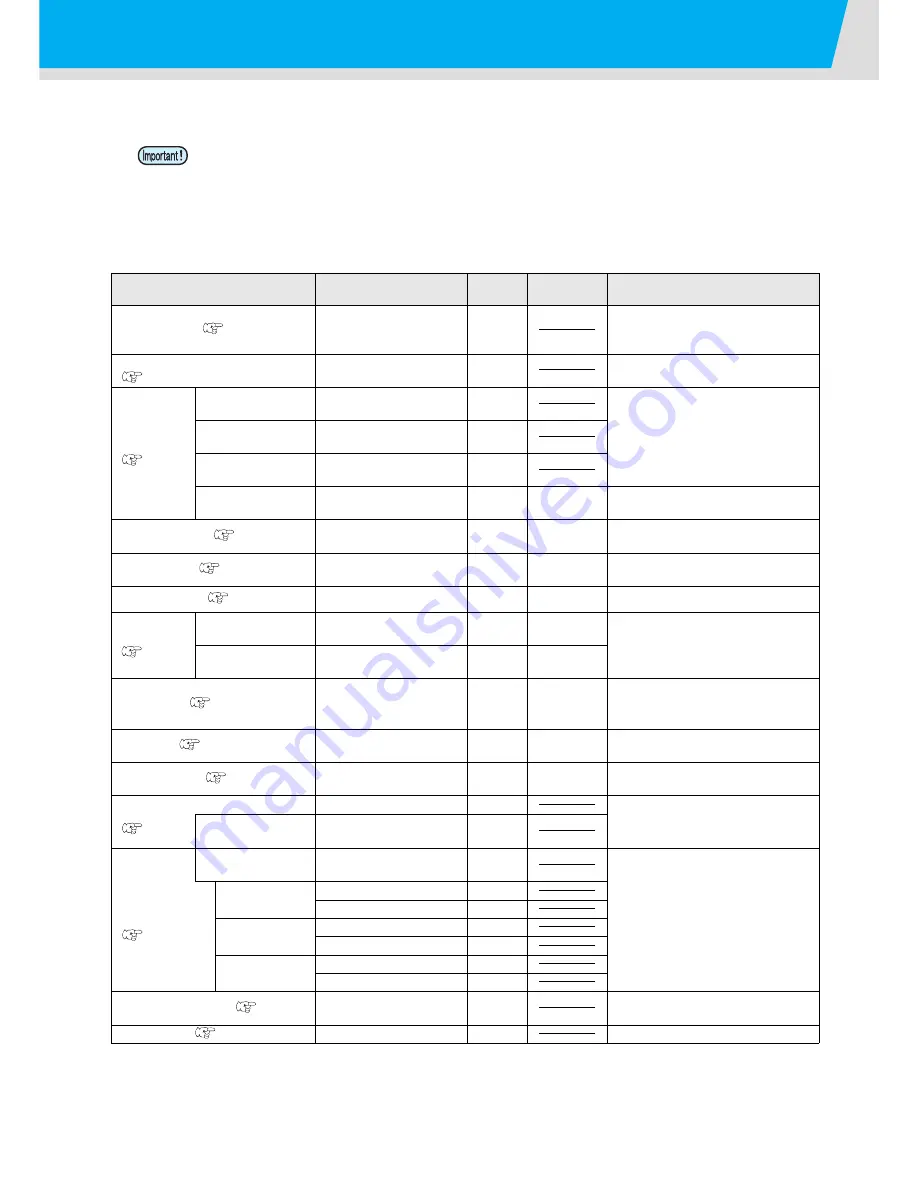

This section describes the overview of each function to be set and set values that can be registered in user

types.

•

About default “HOST” function

You can operate this by the setting value specified in RIP software.

When you set to other than “HOST”, it operates by that setting value, not by the instruction from RIP

software.

Depending on RIP software, there are some functions that cannot be instructed by software. In such a

case, it operates by the setting value of “When no instruction from RIP exists”.

• For the specifying method with the RIP software, refer to the operation manual of the RIP software.

Function name

Set value

Default

When no instruction

from RIP exists

*1

*1. This is the setting value to be used for printing when setting value is not specified at the RIP software (host) side, or, you give priority

to the setting value at the machine side, even if you set “Host” to the type registration of this machine.

Outline

FEED COMP. (

P.2-32)

-9999 ~ 0 ~ 9999

0

Used to print a pattern for

correcting a media-feeding rate and

correct it.

DROP. POS CORRECT

(

P.2-34)

-40.0 ~ 0 ~ 40.0

0

Used to adjust the dot position in go

and return printing.

HEATER

(

P.2-26)

OFF/ 20 ~ 60

°

C

(OFF/ 68 ~ 140

°

F)

OFF

Sets heater conditions.

POST

OFF/ 20 ~ 60

°

C

(OFF/ 68 ~ 140

°

F)

OFF

POST

OFF/ 20 ~ 70

°

C

(OFF/ 68 ~ 158

°

F)

OFF

EXTERNAL

HEATER

OFF/ON

OFF

Sets ON/OFF of the external

heater.

LOGICAL SEEK(

P.3-4)

HOST / ON / OFF

HOST

ON

Sets the scan movable area during

printing.

INK LAYERS (

P.3-11)

HOST /1 ~ 9

HOST

1

Sets the number of layers in which

ink is to be applied.

DRYING TIME (

P.3-4)

HOST /0.0 ~ 9.9 sec

HOST

0 sec

Sets the drying time of ink per scan.

MARGIN

(

P.3-6)

LEFT

HOST / -10 ~ 85mm

(1mm unit)

HOST

0 mm

Sets a non-printing area along the

right and left edges of the media.

RIGHT

HOST / -10 ~ 85mm

(1mm unit)

HOST

0 mm

REFRESH (

P.3-11

)

HOST / Lv.0 (Refresh

interval long) ~ 3 (Refresh

interval short)

HOST

Lv.3

Refreshes the print heads during

printing.

VACUUM (

P.3-11)

HOST / STANDARD /

STRONG

HOST

STANDARD

Sets the absorbability of the media.

FEED SPEED (

P.3-11)

HOST / 10 ~ 200%

*2

*2. When you set this to “100%” or more, required time for completion of printing will be shortened. However, enough drying time cannot

be ensured and it may affect the image quality.

HOST

100%

Changes the media feeding speed

in printing.

MAPS

(

P.3-7)

OFF/ON

OFF

Perform setting to reduce stripes

between passes.

PRINT SPEED

ADJUST

-50 to +50%

0%

AUTO

CLEANING

(

P.3-9)

OFF, PAGE,

LENGTH, TIME

OFF

Sets the automatic cleaning

operation for the head performed

before printing or during printing.

PAGE

INTERVAL 1 to 1000 page

1 page

TYPE

NORMAL / SOFT / HARD

SOFT

LENGTH INTERVAL 0.1 to100.0m

0.5m

TYPE

NORMAL / SOFT / HARD

SOFT

TIME INTERVAL 10 to 120 min

10 min

TYPE

NORMAL / SOFT / HARD

SOFT

INTERVAL WIPING (

P.3-10)

3 to 255 minutes

, OFF

OFF

Sets the wiping operation during

printing.

HEAD GAP (

P.2-5

)

1.5 to 7.0mm

2.0 mm

Sets the head gap.

Содержание TS500-1800

Страница 1: ...MIMAKI ENGINEERING CO LTD URL http eng mimaki co jp D202330 13 Original instructions...

Страница 12: ...xi...

Страница 30: ...1 18...

Страница 134: ...4 28...

Страница 161: ...Warning labels 6 7 Appendix 6 1 Reorder M903239 3 Reorder M903330 4 Reorder M901549 5 Reorder M903404 6 Reorder M908973...

Страница 177: ...Function Flowchart 6 23 Appendix 6...

Страница 182: ...6 28...

Страница 184: ...NH FW 1 4 MIMAKI ENGINEERING CO LTD 2013...