Copyright Meritor, Inc., 2021

MM-96147 / Revised 03-21

Page 53

(16579)

Printed in USA

8 Easy Service

Lubrication

Universal Joint

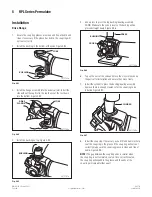

Lubricate the universal joints at the grease fi tting until grease fl ows

from the bearing cup seals on all four trunnions. Use a grease

that meets Meritor specifi cation O-634-B, NLGI Grade 2 with EP

additive. Figure 8.11.

• If grease does not purge from all four trunnion seals:

Follow the steps below.

a. Move the assembly UP-AND-DOWN or SIDE-TO-SIDE

while you apply grease gun pressure. Figure 8.12.

b. Loosen the bearing cup capscrews. Add grease until

grease purges from the four seals.

c. Tighten the bearing cup capscrews after grease purges.

• If grease still does not purge from all four trunnion

seals:

Remove the universal joint and correct the problem.

If you cannot, replace the universal joint.

New grease must

flow at all four seals.

4001852a

Fig. 8.11

4001853a

Fig. 8.12

Slip Yoke Splines

NOTE:

When you lubricate a slip yoke, the splined shaft can be

either fully extended or fully collapsed.

Add a grease that meets Meritor specifi cation O-634-B, NLGI

Grade 2 with EP additive, to the slip yoke grease fi tting. Six to eight

pumps or approximately one oz (28 grams) is suffi cient to lube the

splines. Figure 8.13.

4001847a

Fig. 8.13