Copyright Meritor, Inc., 2021

MM-96147 / Revised 03-21

Page 33

(16579)

Printed in USA

5 RPL Series Permalube

4001817c

Fig. 5.60

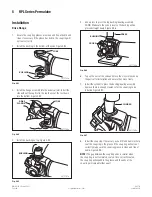

Strike the yoke ear with a brass or copper hammer to ensure that

the universal joint moves freely. Figure 5.61.

Move the joint with your hand

to ensure free movement.

4001818c

Fig. 5.61

Driveline

WARNING

If you do not correctly install the universal joint and end yoke, the

bushings will not correctly seat in the yoke, which can cause the

capscrews that secure the universal joint to fatigue under normal

operating conditions. Serious personal injury and damage to

components can result.

WARNING

You must position the wing bushing’s machined keyway against

the machined keyway of the end yoke ears when you install

a universal joint. Ensure that the arrows stamped on the wing

bushing point TOWARD the end yoke, and the universal joint

weld strap faces the driveline and AWAY from the yoke.

CAUTION

A broken weld strap can cause a wing bushing to rotate. When

a bushing rotates, it’s possible to assemble it into the yoke

backward. To ensure correct assembly and prevent damage

to components, you must insert both of the wing bushing’s

machined keyways into the yoke.

1. Before you install the capscrews, check that the universal

joint is fully seated in the end yoke. The arrows on the wing

bushing should point toward the coupling yoke. Figure 5.62.

4001836b

Machined keyways

are on this side.

WELD STRAP

Arrows toward

coupling yoke.

Fig. 5.62

2. If necessary, tap the universal joint with a brass or copper

hammer to ensure it is fully seated. Figure 5.63.

4001891b

Machined

keyways

are on

this side.

WELD STRAP

YOKE NIBS

Arrows indicate

direction of

installation.

Fig. 5.63

NOTE:

Any time a universal joint is disconnected, new capscrews

must be used during reassembly.

3. Install the new capscrews.

4. Use a torque wrench to alternately tighten the capscrews to

115-135 lb-ft (155-183 Nm). Figure 5.64.