Copyright Meritor, Inc., 2021

MM-96147 / Revised 03-21

Page 46

(16579)

Printed in USA

6 Full-Round

NOTE:

Any time a universal joint is disconnected, new capscrews

must be used during reassembly.

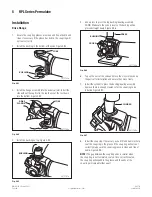

5. Install new capscrews and hand-tighten them through the

bearing cover plate and into the yoke.

6. Repeat Step 2 to Step 5 to install the second bearing cup.

• If the cover plate will not seat fl ush against the yoke

surface:

Remove each bearing cup from the yoke bore.

Check the bottom of each bearing cup. If you fi nd a needle

bearing, replace the bearing cup.

7. Use a torque wrench to alternately tighten the capscrews to

correct specifi cations. Refer to Table B. Figure 6.14.

4001842a

Fig. 6.14

Table B: Torque Specifi cations – Full-Round

Driveline

Series

"A" Inches

(mm)

Thread

Size

Inches

Torque Specs

lb-ft (Nm)

16N

5.31 (134.87)

5/16-24

26-35 (35-47)

17N

6.09 (154.69)

3/8-24

38-48 (51-65)

176N

7.00 (177.8)

3/8-24

38-48 (51-65)

18N

7.55 (191.77)

3/8-24

38-48 (51-65)

YOKE GAUGE

TOOL

“A” dimension

across yoke

ears determines

end yoke/universal

joint series.

“A”

Identifies

driveline

series

4001848a

Lubrication

Universal Joint

After installation into the end yokes, lubricate the universal joints at

the grease fi tting until grease fl ows from the bearing cup seals on

all four trunnions. Use Meritor grease specifi cation O-634-B, NLGI

Grade 2 with EP additive. Figure 6.15.

• If grease does not purge from the seals:

Follow the

steps below.

New grease must

flow at all four seals.

Shown without end

yokes for clarity.

4001843a

Fig. 6.15

a. Move the assembly UP-AND-DOWN or SIDE-TO-SIDE while

you apply grease gun pressure. Figure 6.16.

4001844a

Fig. 6.16

b. Loosen the bearing cup capscrews. Add grease until grease

purges from the seals.

• If grease still does not purge from all four trunnion

seals:

Remove the universal joint and correct the problem.

• If you cannot determine the problem:

Replace the

universal joint.

c. Tighten the capscrews. Refer to Table B.