EX1001, EX2001, EX8017

3

Discharge Tube

- This tube carries

compressed air from the pump to the

check valve. This tube becomes very hot

during use. To avoid the risk of severe

burns, never touch the discharge tube.

Check Valve

- One-way valve that

allows air to enter the tank, but

prevents air in the tank from flowing

back into the compressor pump.

Tank Drain

- This valve is located on

the bottom of the tank. Use this valve

to drain moisture from the tank daily

to reduce the risk of corrosion.

Reduce tank pressure below 10 psi by

pulling the safety valve, then drain

moisture from tank. Drain daily to

avoid tank corrosion.

LUBRICATION

This is an oilless product and

does not

require lubrication to operate.

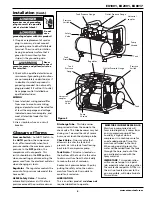

Installation

(Cont.)

Improper use of grounding

plug can result in a possible

risk of electrical shock!

Do not

use a

grounding adapter with this product!

2. If repair or replacement of cord or

plug is necessary, do not connect

grounding wire to either flat blade

terminal. The wire with insulation

having an external surface that is

green (with or without yellow

stripes) is the grounding wire.

Never

connect

green (or green and yellow) wire to a

live terminal.

3. Check with a qualified electrician or

serviceman if grounding instructions

are not completely understood, or if

in doubt as to whether product is

properly grounded. Do not modify

plug provided; if it will not fit outlet,

have proper outlet installed by a

qualified electrician.

WIRING

1. Local electrical wiring codes differ

from area to area. Source wiring,

plug and protector must be rated for

at least the amperage and voltage

indicated on motor nameplate, and

meet all electrical codes for this

minimum.

2. Use a slow blow fuse or a circuit

breaker.

Glossary of Terms

Pressure Switch

- Auto/Off Switch - In

the

AUTO

position, the compressor

shuts off automatically when tank

pressure reaches the maximum preset

pressure. In the

OFF

position, the

compressor will not operate. This

switch should be in the

OFF

position

when connecting or disconnecting the

power cord from the electrical outlet or

when changing air tools.

Regulator

- The regulator controls the

amount of air pressure released at the

hose outlet.

ASME Safety Valve

- This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

Figure 2

Pump

Shroud

Safety

Valve

Pressure

Switch

Tank

Tank

Drain

Universal

coupler

Tank Pressure Gauge

Outlet Pressure Gauge

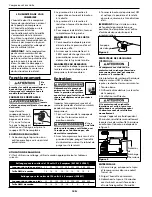

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will

form into droplets as it comes from

an air compressor pump. When

humidity is high or when a

compressor is in continuous use for

an extended period of time, this

moisture will collect in the tank.

When using a paint sprayer, this

water will be carried from the tank

through the hose, and out of the

gun as droplets mixed with the

spray material.

IMPORTANT:

This condensation

will cause water spots in a paint

job, especially when spraying other

than water based paints. A filter in

the air line, located as near to the

gun as possible, will help eliminate

this moisture.

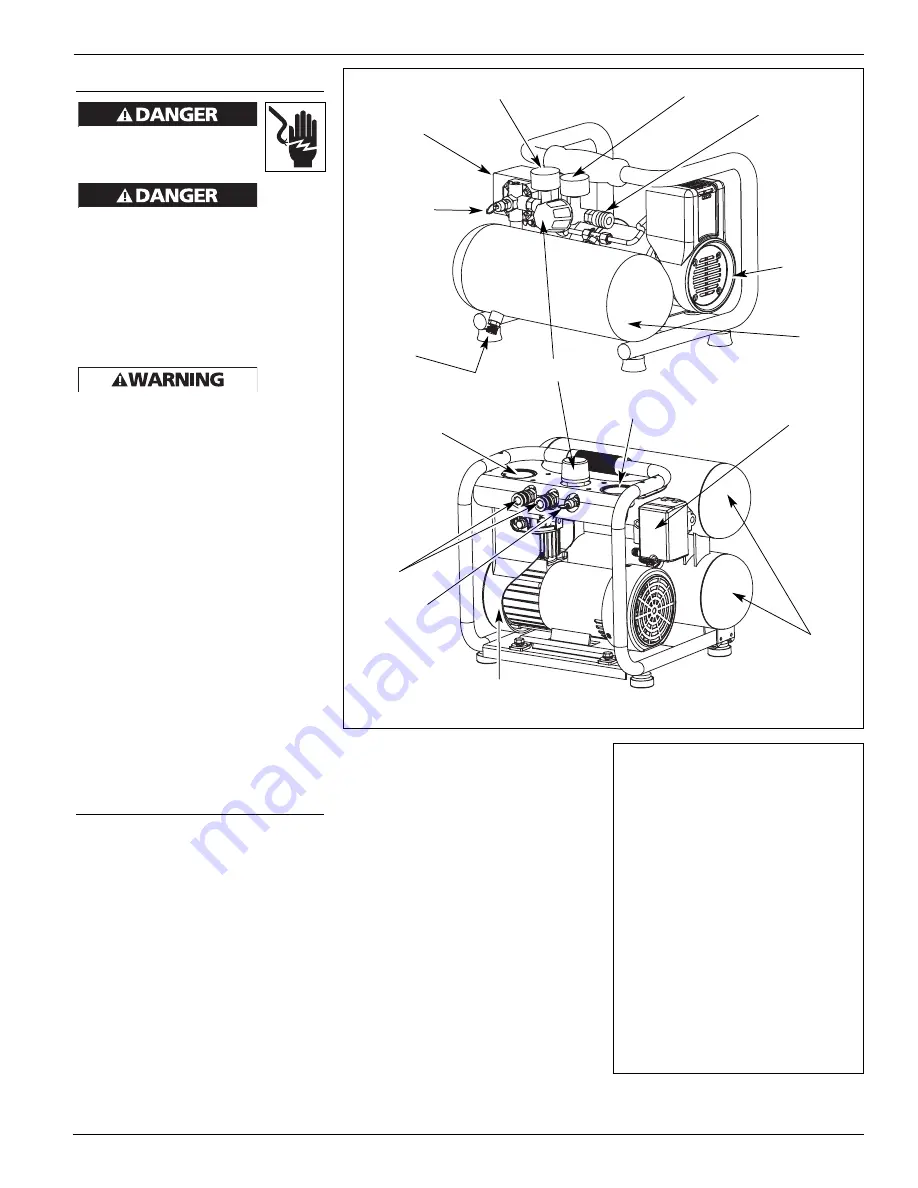

Regulator

Pump

Shroud

Pressure

Switch

Universal

coupler

Tank

Pressure

Gauge

Outlet Pressure Gauge

Tank

Safety

Valve

www.maxustools.com