Maintenance

Disconnect power source

then release all pressure

from the system before

attempting to install, service,

relocate or perform any maintenance.

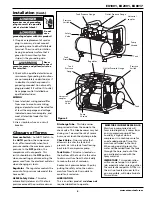

The compressor should be checked

often for any visible problems and the

following maintenance procedures

should be performed each time the

compressor is used.

1. Pull ring on safety valve and allow it

to snap back to normal position.

Safety

valve

must be replaced if it cannot be

actuated or it leaks air after ring is

released.

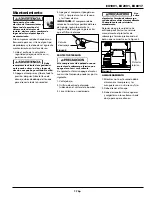

2. With compressor shut off and

pressure released: Drain moisture

from tank by opening drain valve

underneath tank (See Figure 4).

3. Turn power OFF and clean dust and

dirt from motor, tank, and air lines.

IMPORTANT:

Unit should be located

as far from spraying area as hose will

allow to prevent over-spray from

clogging intake port.

Operation

Do not

attach air

chuck or other tool to open end of

hose until start-up has been completed

and unit checks OK.

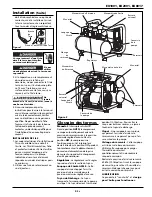

ASME SAFETY VALVE

Do not

remove

or attempt to adjust the safety valve!

This valve should be

checked under

pressure occasionally

by pulling the ring by

hand. If air leaks after

ring has been

released, or valve is stuck and cannot

be actuated by ring, it MUST be

replaced.

REGULATOR KNOB

1. This knob controls air pressure to an

air operated tool, or paint spray gun.

2. Turning knob clockwise increases air

pressure at outlet.

3. Turning counterclockwise will lower

air pressure at outlet.

4. Fully counterclockwise will shut off

flow of air completely.

OUTLET PRESSURE GAUGE

1. This gauge shows at-a-glance, air

pressure at outlet. Air pressure is

measured in pounds per square inch

(psi).

2. Be sure this gauge reads ZERO

before changing air tools or

disconnecting hose from outlet.

TANK PRESSURE GAUGE

Gauge shows pressure in tank

indicating compressor is building

pressure properly.

4

Figure 4

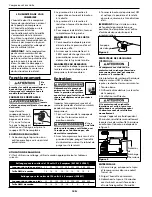

THERMAL OVERLOAD PROTECTOR

This

compressor is equipped with an manual

reset thermal overload protector which

will shut off motor if it becomes

overheated.

If thermal overload protector shuts

motor OFF frequently look for the

following causes:

1. Low voltage

2. Clogged intake port (located on

pump crankcase)

3. Lack of proper ventilation

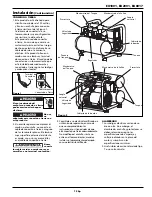

If the

thermal

overload protector is actuated, the motor

must be allowed to cool down for 30

minutes before manually resetting.

After the unit has cooled down for 30

minutes, manually reset the thermal

overload protector by pushing the

button shown in Figure 5.

STORAGE

1. When not in use, store hose and

compressor in a cool, dry place.

2. Drain tank of moisture

3. Disconnect hose and hang open ends

down to allow any moisture to drain.

Drain

Valve

Oilless Compressors

Figure 3

Figure 5

Thermal

overload

protector

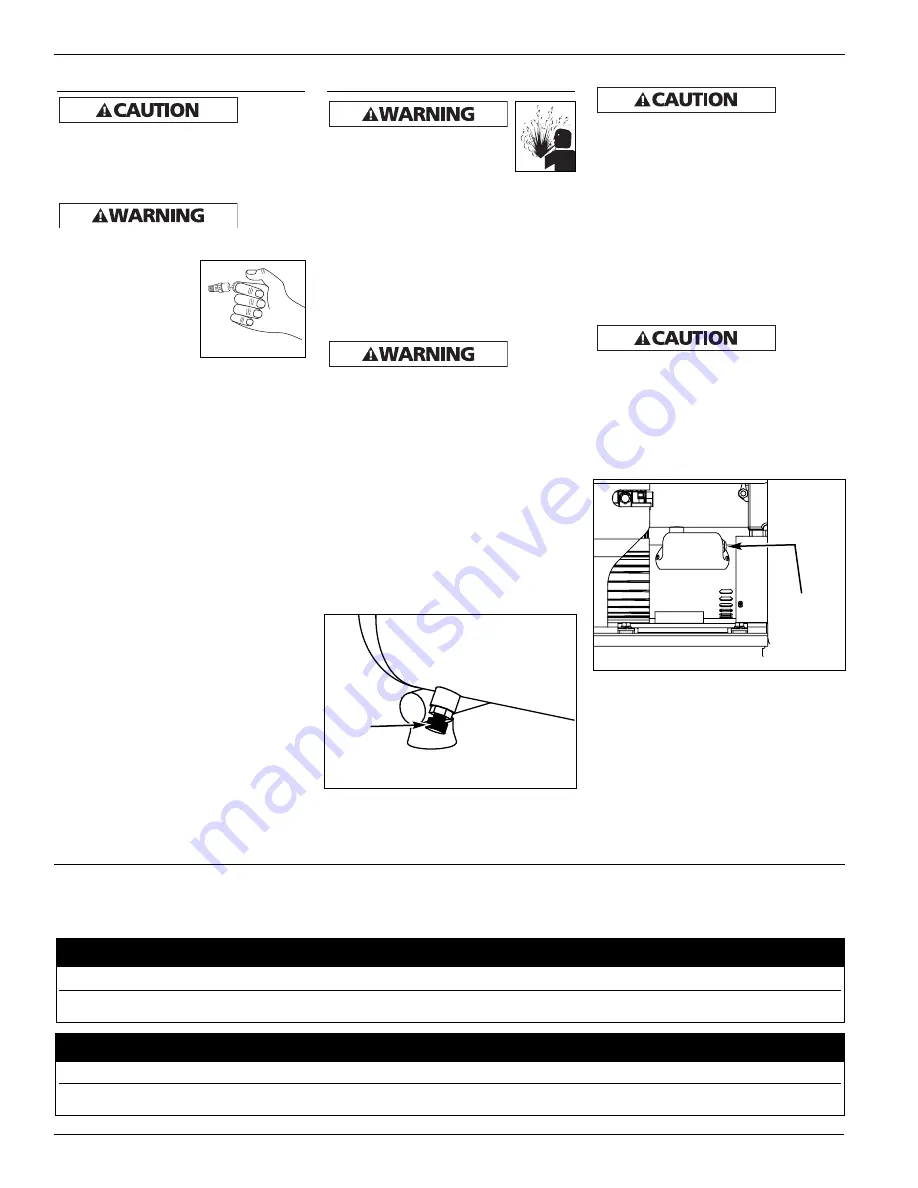

EXTENSION CORD USE

If an extension cord has to be used, use the appropriate cord based on the charts below.

www.maxustools.com

Extension cords for 120V / 3 to 4 Amp Units (EX1001, EX2001)

Length of Cord in Feet

25 50 100

150

200

250

300

400

500

AWG Size of Cord

18 18 16

14

12

12

10

10

8

Extension cords for 120V / 6 to 8 Amp Units (EX8017)

Length of Cord in Feet

25 50 100

150

200

250

300

400

500

AWG Size of Cord

18

16

12

10

10

8

6

6

6