MAINTENANCE

Printed in U.S.A.

119

50950436

/

H0521

1 .

Park the machine with one of the travel

motor drain/fill hole plugs (O, Fig. 75) at

the bottom .

2 .

Perform the “Mandatory Safety

Shutdown Procedure” on page 16 .

3 .

Position a waste oil collection container

with a 1 quart/liter (+ 0 .10 quarts/liters)

underneath the drain/fill hole plug and

remove the lower plug .

IMPORTANT:

Always dispose of hydrau-

lic fluids according to environmental laws

or take to a recycling center for proper

disposal. DO NOT pour onto the ground or

down a drain.

4 .

Remove a second plug near the top .

5 .

Remove the drain/fill hole plug and allow

the oil to drain completely .

6 .

Reinstall the lower drain/fill hole plug.

Tighten securely .

7 .

Through the top drain/fill plug, fill the

travel motor front case with the same

grade and type oil used in the hydraulic

system . Each travel motor requires 345 -

375 ml (0 .36 - 0 .39 qt .) of hydraulic oil .

8 .

Reinstall the upper drain/fill hole plug.

Tighten securely .

9 .

Test the drive system and check for leaks .

Tracks

Track Maintenance

Inspect the tracks daily for damage and wear .

IMPORTANT:

To avoid damaging the

tracks and to ensure maximum track life,

refer to “Rubber Track Use Cautions and

Tips” on page 72.

Observe the following conditions to extend

track life:

• Avoid traveling or turning on broken stone,

jagged rock, metal or other material that could

damage or cut the tracks .

• Avoid traveling on riverbeds or areas with

soft rocks that could become stuck in the

tracks, which could cause damage to the tracks

or cause the tracks to slip off.

• Avoid using the machine on the seashore .

Sea salt can corrode the metal cores inside the

tracks .

• Immediately wipe any spilled fuel, oil, salt

or chemical solvents off of the tracks, as these

substances can corrode the coupling in the

metal cores in the tracks, causing corrosion

and peeling .

Avoid traveling on freshly paved roads or on

hot surfaces (e.g. fires, metal sheets exposed to

direct sunlight, etc .) . Hot surfaces can damage

the lugs or cause irregular wear .

Avoid moving earth in area where the tracks

may slip, which can cause excessive lug wear .

Track Replacement

Keeps hands clear from between the

track and the idler when installing

tracks. Crushing of body parts and

amputation can result.

Fig. 76 - Tension Stop Cylinder

Содержание MUSTANG 1050RT

Страница 63: ...Indicators and Controls 50950436 H0521 60 Printed in U S A ...

Страница 109: ...50950436 H0521 106 Printed in U S A ...

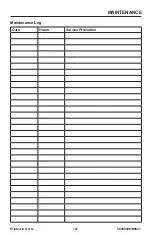

Страница 127: ...MAINTENANCE 50950436 H0521 124 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Страница 128: ...MAINTENANCE Printed in U S A 125 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Страница 129: ...MAINTENANCE 50950436 H0521 126 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Страница 130: ...MAINTENANCE Printed in U S A 127 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Страница 131: ...MAINTENANCE 50950436 H0521 128 Printed in U S A ...

Страница 142: ...Troubleshooting Printed in U S A 139 50950436 H0521 Error Codes ...

Страница 143: ...Troubleshooting 50950436 H0521 140 Printed in U S A ...

Страница 144: ...Troubleshooting Printed in U S A 141 50950436 H0521 ...

Страница 145: ...Troubleshooting 50950436 H0521 142 Printed in U S A ...

Страница 146: ...Troubleshooting Printed in U S A 143 50950436 H0521 ...

Страница 155: ...50950436 H0521 152 Printed in U S A ...