MAINTENANCE

116

Printed in U.S.A.

IMPORTANT:

Always dispose of hydrau-

lic fluids according to environmental laws

or take to a recycling center for proper

disposal. DO NOT pour onto the ground or

down a drain.

Fig. 72 -

L

Hydraulic Oil Filter

6 .

Remove the hydraulic oil filter (L, Fig.

72), using a filter wrench if necessary.

Carefully clean the filter head mounting

surface with a clean cloth .

7 .

Apply a coating of clean oil on the new

oil filter gasket. Install the filter and

tighten 3/4 rotation past the point where

the gasket contacts the filter head.

8 .

Re-install and tighten the drain plug .

9 .

Remove hydraulic dipstick/oil fill cap (I,

Fig . 69) and add hydraulic oil until the

level reaches the FULL marking (J, Fig .

70) on the dipstick .

10 .

Replace and tighten the hydraulic oil fill

cap . Close and lock the hydraulic tank

cover . Close the engine compartment .

NOTE:

Refer to “Fuel System

Maintenance” on page 112 for proper

hydraulic oil grade and type. Hydraulic oil

capacity listed is approximate.

11 . Start the machine . Cycle through all

hydraulic functions several times to purge

air from the hydraulic system . Shut down

the machine .

12 . Check the machine for hydraulic oil

leaks . Correct any leaks as required .

50950436

/G

0

12

1

13 . Add oil to the hydraulic system as

required until the level reaches the FULL

marking on the dipstick . Replace and

tighten the hydraulic oil dipstick/fill cap.

Engine Cooling System

IMPORTANT:

Check the cooling system

every day to prevent overheating, loss of

performance or engine damage.

Checking Coolant Level

Fig. 73 -

M

N

Cooling System

1 .

Open the rear door . Check the coolant

level in the coolant recovery tank (M, Fig .

73) on the inside of the rear door . The

coolant recovery tank must be 1/3 to 1/2

full with a cold engine and 2/3 to 3/4 full

with a hot engine .

2 .

Allow the coolant to cool . Do not remove

the cap when the coolant is hot . Serious

burns may occur .

3 .

Add premixed coolant, 50% water and

50% ethylene glycol, and supplemental

coolant additives (SCAs) to the recovery

tank if the coolant level is low .

Cleaning Cooling System

1 .

Park the loader on a level surface .

2 .

Perform the “Mandatory Safety

Shutdown Procedure” on page 16 .

3 .

Wait until the engine has cooled .

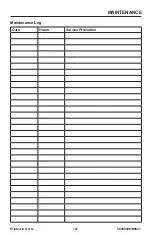

Содержание MUSTANG 1050RT

Страница 63: ...Indicators and Controls 50950436 H0521 60 Printed in U S A ...

Страница 109: ...50950436 H0521 106 Printed in U S A ...

Страница 127: ...MAINTENANCE 50950436 H0521 124 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Страница 128: ...MAINTENANCE Printed in U S A 125 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Страница 129: ...MAINTENANCE 50950436 H0521 126 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Страница 130: ...MAINTENANCE Printed in U S A 127 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Страница 131: ...MAINTENANCE 50950436 H0521 128 Printed in U S A ...

Страница 142: ...Troubleshooting Printed in U S A 139 50950436 H0521 Error Codes ...

Страница 143: ...Troubleshooting 50950436 H0521 140 Printed in U S A ...

Страница 144: ...Troubleshooting Printed in U S A 141 50950436 H0521 ...

Страница 145: ...Troubleshooting 50950436 H0521 142 Printed in U S A ...

Страница 146: ...Troubleshooting Printed in U S A 143 50950436 H0521 ...

Страница 155: ...50950436 H0521 152 Printed in U S A ...