MAINTENANCE

Printed in U.S.A.

113

50950436

/

H0521

diesel fuel, which is dyed red for identifica

-

tion. It may take several fillings of the fuel

tank before the red dye is purged from the

fuel system.

IMPORTANT:

Service the fuel system

only in an absolutely clean environment to

avoid contamination.

Adding Fuel

Static electricity can produce danger-

ous sparks at the fuel-filling nozzle. Do

not wear polyester, or polyester-blend

clothing while fueling. Before fueling,

touch the metal surface of the machine

away from the fuel fill to dissipate any

built-up static electricity. Do not re-en-

ter the machine but stay near the fuel

filling point during refueling to mini

-

mize the buildup of static electricity. Do

not use cell phones while fueling. Make

sure the static line is connected from

the machine to the fuel truck before

fueling begins.

Ultra-Low Sulfur Diesel (ULSD) poses

a greater static ignition hazard than

earlier diesel formulations. Avoid death

or serious injury from fire or explosion;

consult with your fuel or fuel system

supplier to ensure the entire fuel

delivery system is in compliance with

fueling standards for proper grounding

and bonding practices.

Though not necessary to leave locked, the use

of a locking fuel cap protects the loader from

fuel theft or fuel system vandalism . The key to

this lockable fuel cap should be secured to the

loader’s key ring . A torque override features

aids in the proper installation of the fuel cap .

It produces an audible click as the o-ring that

seals the cap is properly compressed . To oper-

ate the lockable fuel cap:

1 .

Perform the “Mandatory Safety

Shutdown Procedure” on page 16 .

2 .

Unlock fuel cap (E, Fig . 67) using the

ignition key and remove the fuel cap from

the fuel filler neck.

Fig. 67 -

E

Fuel Filler Cap

3 .

Inspect the wire-mesh fuel strainer

located in the filler neck opening and

remove any accumulated residue . Replace

the strainer if damaged .

4 .

Fill the fuel tank by adding fuel through

the fuel filler neck opening.

IMPORTANT:

Refer to “Check engine oil

level and condition” on page 107 and the

engine operation manual for proper fuels.

Use of improper fuels can cause engine

damage.

5 .

When the fuel tank is full, replace and

lock fuel cap (E) in the fuel filler neck

opening .

Water Separator Inspection/

Maintenance

NEVER service the fuel system while

smoking, while near an open flame, or

after the engine has been operated and

is hot.

Содержание MUSTANG 1050RT

Страница 63: ...Indicators and Controls 50950436 H0521 60 Printed in U S A ...

Страница 109: ...50950436 H0521 106 Printed in U S A ...

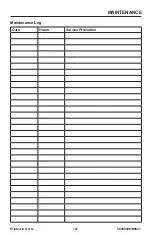

Страница 127: ...MAINTENANCE 50950436 H0521 124 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Страница 128: ...MAINTENANCE Printed in U S A 125 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Страница 129: ...MAINTENANCE 50950436 H0521 126 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Страница 130: ...MAINTENANCE Printed in U S A 127 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Страница 131: ...MAINTENANCE 50950436 H0521 128 Printed in U S A ...

Страница 142: ...Troubleshooting Printed in U S A 139 50950436 H0521 Error Codes ...

Страница 143: ...Troubleshooting 50950436 H0521 140 Printed in U S A ...

Страница 144: ...Troubleshooting Printed in U S A 141 50950436 H0521 ...

Страница 145: ...Troubleshooting 50950436 H0521 142 Printed in U S A ...

Страница 146: ...Troubleshooting Printed in U S A 143 50950436 H0521 ...

Страница 155: ...50950436 H0521 152 Printed in U S A ...