17

GB

W ARNING

The elec tric compress ors mus t be c onnect ed t o a power soc ket

that is saf eguarded by a s uitable differential s witch (magneto

thermal s witch).

ADJUSTING THE W ORKING PRESSURE

(fi g. 11) It is not

always necess ary t o us e the maxi mum wor king pressure, on the

contrar y t he pneumatic tool usually requires l ess press ure. Adjust

the wor king press ure acc urat ely i n compress ors provided with

pressure regulat ors. Release t he knob of the pressure regulat or by

pulling it outwards, adjus t the pr essure t o t he desired value by

turning the knob cloc kwis e to increas e it and anti-clockwise to

decreas e it. O nce t he ideal pr essure has been reac hed, bloc k the

knob by pus hing it downwards (fig. 11). In the case of pressure

regulators supplied wit hout a gauge, t he calibrati on pressure may

be s een on t he graduat ed scale situated on t he c asing of the actual

regulator. I n t he cas e of pr essure r egulators s upplied wit h a gauge,

the calibr ation pressure may be seen on t he act ual gauge.

WARNING: Some press ure regulat ors do not have “pus h to l oc k”,

theref ore si mpl y t urn t he knob t o adjust the press ure.

MAINTENANCE

Befor e ser vicing the compr essor make sure that:

-

the mai n line ON/OFF s witch is on «0».

-

the pressure switc h or the line s witc h is on «0».

-

there is no pr essure in the air tank ( onl y f or model with t ank)

.

The c ompressor generat es c ondens at e t hat accumulates in the

tank

.

The condensat e must be drained from the tank at least once

a wee

k

by opening the discharge tap (fig. 12) underneat h the tank

(only fo

r

model with tank)

.

Be c aref ul if there is any compr essed

air withi n t he c ylinder as th

e

water c ould burst out with some force.

Recommended pressur e 1

÷

2 bar max

.

RECOMMENDED MAINTENANCE

In units

F

wit h 2 poles , replace the whole c onnec ting rod unit every

700 hours of operati on.

In units

F

and FB

wit h 4 poles , repl ace t he whole c onnecting rod

unit ever y 1500 hours of operati on. I n units GMS and VS, replace

the slidi ng bloc ks and the compressi on ring every 1500 hours of

operation.

LUBRICATING THE BEARING S

All the bearings are lubricat ed with grease f or life wit h the

exc eption of the roller c asing fitted on the connecting rod side of

the GMS and VS units whic h is to be was hed wit h sol vent and re-

lubricated with “Kluber Barrierta L 55/2” greas e every 1500 hours

of operation (white greas e). The greas e must completel y fill the

spaces bet ween t he rollers; exc ess lubricant will be expelled during

the i nitial hours of operation.

CLEANING THE FILTER (F-

FB

-ECU-GMS-VS Series-AIRCLIK-F

1)

It is advisabl e to dis mantle t he suc tion filt er ever y 50 hours of use

and to clean t he fi ltering el ement by blowing it wit h compr essed

air, or replac e it if the el ement pointed out by t he arrow is clogged.

HOW TO PROCEED W HEN TRIVIAL ANOMALI ES

ARE ENCOUNTERED Loss of air from the valve underneath

the pressure switch (onl y model with tank)

This inconveni enc e is due to the imperf ect s eal of t he non-return

val ve

;

pr oceed as follows: (fig. 13)

.

Releas e all t he pressure from

the tank

.

Remove the panelling by unscrewing the four securing

screws and lif

t

it. (fig. 13-14) (

F 1 and AIRCLIK

)

.

Unscrew the

hexagonal head of t he val ve (A)(fig.15)

.

C arefull y clean the small

rubber dis k (B) and also its seat (fig.15)

.

Re-fi t ever yt hing

accurat ely

.

Loss of air (F-GMS-VS Series)

This may be due t o the poor seal of one of the fittings. Chec k all

the fi ttings by wetting t hem with s oapy wat er.

The compressor runs but fail s to load

F-GMS-VS series compr essors: (fig.16)

-

This may be due t o a breakage of t he val ve, or a gas ket (B1-

B2). Replace the damaged c omponent.

-

This may be due to a breakage of the valves (C1-C2), or a

gasket

(B1-B2). Repl ace t he damaged component (fig.16B). AirClik-F

1 series (fig. 16A):

-

This may be due to the breakage of t he val ves (C1 - C2) or of

the gas ket (B1). Repl ace t he damaged part (fig. 16A).

The compressor f ails to start

If the compress or has difficult y in s tarting, make sure t hat : -the

mains volt age c orresponds to that indicated on the dat a nameplate

(fi g. 8)

- electrical ext ension cables with uns uitable cross-secti on or

length ar e not used.

-

the room in which the compress or is running is not too cold

(below 0°C)

-

the electric line is efficient (plug connected correctl y, magneto

thermal s witch, fus es not blown)

The compressor f ails to stop (onl y with tan k)

if the compr essor f ails to stop when the maxi mum pressure is

reached, the tank saf et y val ve will trip. Contact t he nearest

aut horised ser vice c entre for t he repairs.

W ARNING

-

Do not unscrew any connec tions wit h t he t ank when under

pressure for any reason whatsoever. Al ways make s ure t hat

the tank is depressurised bef orehand.

-

Do not drill, weld or intentionall y deform t he compressed air

tank.

-

Do not carry out any operati ons on the compress or bef ore it

has been unpl ugged from t he power s oc ket .

-

The room temperat ure f or its c orrect efficienc y is: 0°C +25°C

(MAX 45°C).

- Do not direct j ets of wat er or flammabl e liquids over t he

compressor.

-

Do not plac e fl ammable objec ts near t he c ompress or.

-

When st opped t emporarily during its use, tur n the pressure

switch or t he ON/OFF s witc h t o position «0» (OFF) (t urned-

off).

-

Never direct the jet of air towards peopl e or ani mals (fig. 24).

-

Do not transport the compr essor when the tank is pr essurised.

-

Be aware that s ome c omponents of the c ompressor s uch as

the head and delivery hos es may r each high t emperat ures,

theref ore do not touch the t o avoid getti ng burned (fig. 10).

-

Transport t he compress or by lifting or pulling it with the

appropriate grips or handl es (fig. 5 - 6).

-

Children and animals must be kept away from t he area in

which t he mac hine is running. If the compress or is used f or

painti ng: a) Do not work in closed areas or near free flames b)

Make sure t hat t he area in whic h you are wor king has a good

change of air c) Protect nos e and mouth usi ng an appropriate

mas k (fig. 18).

-

Do not us e t he c ompressor if the elec tric cable or t he plug is

damaged.

-

Contac t the neares t aut horised servic e centr e for the

replacement with an original component .

-

If it is plac ed on a shelf or a surfac e t hat is rais ed off t he

ground, it must be sec ured appropriat el y t o pr event it fr om

tipping of f when runni ng.

-

Do not insert objects or your hands inside the saf et y grating to

avoid physical damage and also damage t o the compress or

(fig. 19).

-

Do not use t he compress or to threaten people or ani mals to

avoid s erious i njuries.

-

Always unplug the compressor from the power soc ket when

you have finished using it.

ELECTRIC COMPRESSOR MODEL (GMS-VS-AIRCLIK-F 1-F)

Maxi mum running press ure: 8.5 bar

Maxi mum wor king press ure: 8 bar

ELECTRIC COMPRESSOR MODEL (FB 210)

Maxi mum running press ure: 10. 5 bar

Maxi mum wor king press ure: 10 bar

NOTE:

The c ompressor t anks have been manufact ured in c omplianc e with

th

e

87/ 404/EC Directi ve f or the European mar ket

.

The

compressors have been manufac tured in c omplianc e with th

e

98/ 37/ EC Directive f or the European mar ket

.

Содержание AC1300

Страница 4: ...4 ...

Страница 5: ...5 ...

Страница 6: ...6 ...

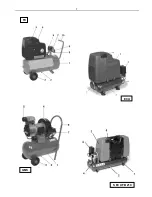

Страница 7: ...7 FX ECU GMS S ECU FB 210 ...

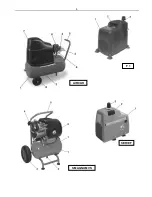

Страница 8: ...8 F 1 AIRCLIK SERIE F S MAGNUM VS ...

Страница 54: ...Cod 734 637 0000 02 2008 ...