S12800 Routing Switch Installa

tion Manual V1.0

Maipu Confidential & Proprietary Information

Page 133

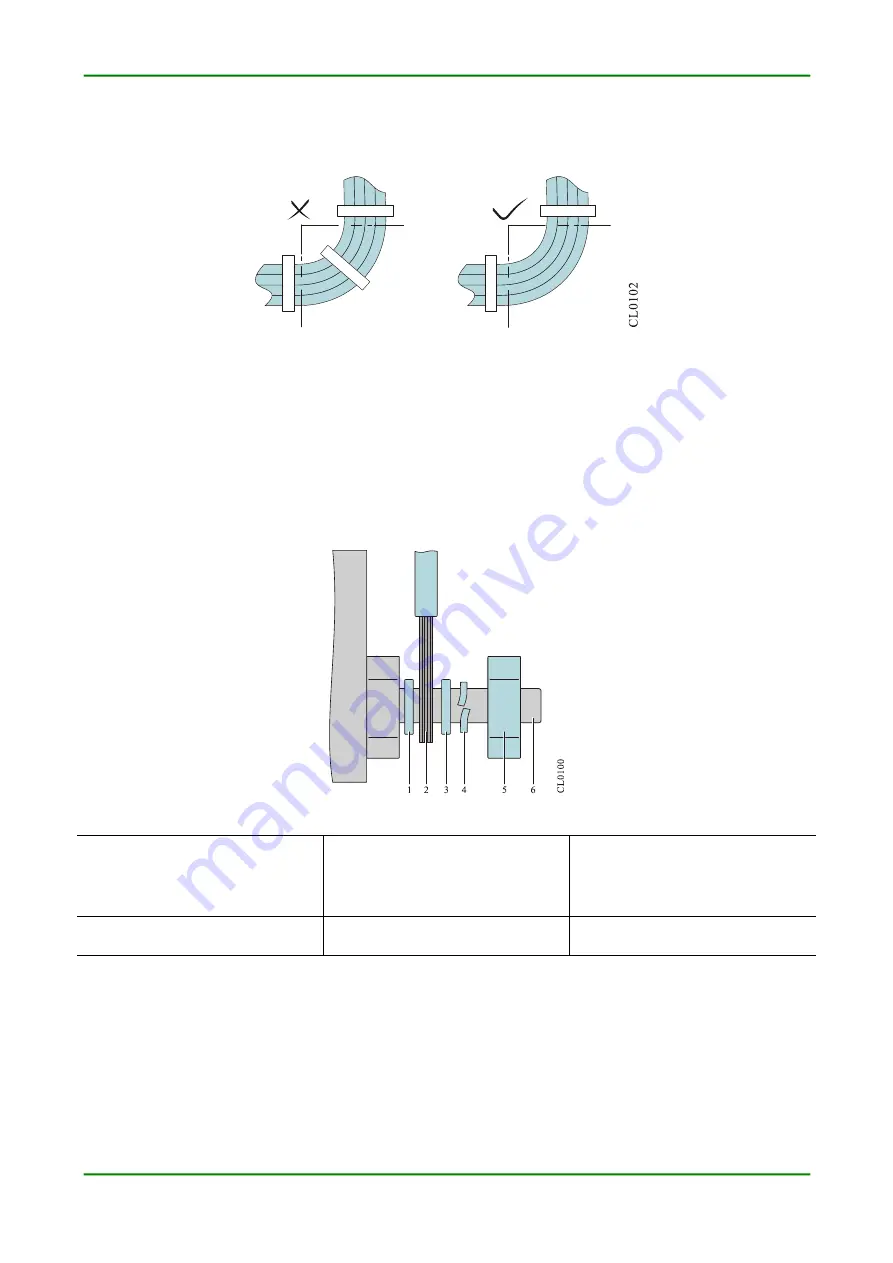

When the cables need to bend, bundle before the cables bend, but the cable tie cannot be

bundled to the bent area, so as to avoid greater stress in the cable, leaving the cable core

rupture, as shown in the following figure.

Appendix figure F-5 The diagram of bent-bundling the cables

The power cables cannot be bundled to the guide rail of the moving parts.

For the power cables connected to moving parts, such as the ground wire, reserve some

margin after assembling, so as to prevent the cables from bearing the stress. When the

moving parts reach the installation location, ensure that the extra cable does not contact

with the heat source, sharp, sharp edges, etc. When the heat source cannot be avoided,

the cable should adopt the high-temperature cable.

Use the screwed cable to connect the terminal, the screws or nuts should be securely

fastened, and take anti-loosening measures, as shown in the following figure.

Appendix figure F-6 The cabling fixing

1.Flat pad

4. Spring pad nut 5. 6. threaded

post

2.Cable

3.Plat pad

4. Spring pad

5. Nut

6. Threaded post

For the hard power cables, fix the cables near to the termination, so as to prevent

generating the stress on the termination and cable.

Do not use self-tapping screws to fasten the terminals.

The same type of power cables in the same direction should be bundled into the cable

bundle. The cables within the cable bundle should be clean and straight. The cable ties

should be bundled according to the following table:

Appendix table F-1 The cable tie bundling