46-605 Flanged External Cage Float Actuated Liquid Level Switches

7

2.0

Reference Information

2.1

Description

Flanged External Cage liquid level switches are completely

self-contained units designed for side mounting to a vessel

or tank with threaded or flanged pipe connections.

2.2

Theory of Operation

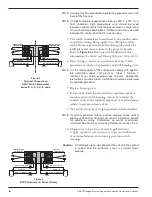

The design of float-operated level switches is based upon

the principle that a magnetic field will not be affected

by non-magnetic materials such as 316 stainless steel

The float moves a magnetic attraction sleeve within a

non-magnetic enclosing tube and actuates a magnetic

switch mechanism. The enclosing tube provides a pressure

seal to the chamber and therefore to the process.

2.3

Operating Cycle

As the liquid level rises in the chamber, the float moves the

magnetic attraction sleeve up within the enclosing tube

and into the field of the switch mechanism magnet. As a

result, the magnet is drawn in tightly to the enclosing

tube, causing the switch to trip making or breaking an

electrical circuit. Refer to

Figure 4

.

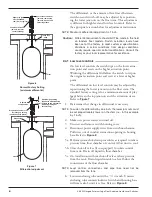

As the liquid level falls, the float drops and moves the

attraction sleeve out of the magnetic field, releasing the

switch mechanism magnet. The tension spring ensures the

return of the switch in a snap action. Refer to

Figure 5

.

Tandem float units incorporate two floats which operate

independently. They are arranged so that the lower float

actuates the upper switch mechanism while the upper float

actuates the lower switch mechanism. The upper float is

attached to the lower attraction sleeve by means of a hol-

low stem. The lower float attaches to the upper attraction

sleeve with a solid stem which extends upward through the

upper float and stem assembly.

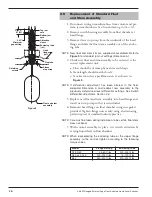

2.4

Switch Differential Adjustment

The standard differential of Flanged Cage float models

with one switch may be field adjusted. Adjustment may be

necessary if a wider differential needs to be set to overcome

switch chatter caused by the process.

NOTE: This procedure may be applied to single switch models only.

Enclosing tube

(non-magnetic)

Sleeve (magnetic)

Float

Normal

operating level

Magnet

Return

Spring

Pivot

Figure 4

Low level

Swing out

position

Figure 5