6

46-605 Flanged External Cage Float Actuated Liquid Level Switches

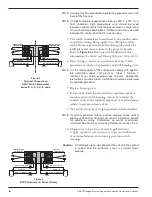

Internal Circuit

(Right) Switch

1

2

3

Load

Load

Line

4

5

6

Internal Circuit

(Left) Switch

Load

Load

Close on high level

Close on high level

Common

Common

Close on low level

Close on low level

Line

Figure 2

Terminal Connections

DPDT Switch Mechanism

Series B, C, D, F, R, 8, and 9

NOTE: Housing must be grounded via protective ground screw in the

base of the housing.

NOTE: On high temperature applications (above +250° F [+121° C] in

float chamber), high temperature wire should be used

between control and first junction box located in a cooler area.

On non-hazardous applications, flexible conduit may be used

between the control and the first junction box.

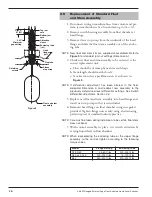

5. The switch terminals are located next to the conduit outlet

to facilitate wiring. Bring supply wires through conduit

outlet. Route extra wire around enclosing tube under the

baffle plate and connect them to the proper terminals.

Refer to

Figure 2 or 3

or your switch bulletin for this

information. See

Switch and Housing Reference, Section 6.2.2.

6. Dress wiring to ensure no interference or contact with

movement of switch, or replacement of switch housing cover.

NOTE: It is the responsibility of the customer to comply with applica-

ble installation codes and practices. Class I, Division 1

locations may contain explosive gas mixtures. Appropriate

precautions must be taken. Installation should be performed

by qualified personnel.

7. Replace housing cover.

8. If control has been furnished with an explosion proof or

moisture proof switch housing, it must be sealed at the

conduit outlet with a suitable compound or non-hardening

sealant to prevent entrance of air.

9. Test switch action by varying liquid level in float chamber.

NOTE: If switch mechanism fails to function properly, check vertical

alignment of control housing and consult installation bulletin

for additional wiring information on switch mechanism

furnished. See

Switch and Housing Reference, Section 6.2.2.

10. Check cover to base fit to be certain gasketed joint

is tight. A positive seal is necessary to prevent infiltration

of moisture-laden air or corrosive gasses into switch

housings.

Caution:

In hazardous areas, do not power the unit until the conduit

is sealed and the enclosure cover is screwed down

securely.

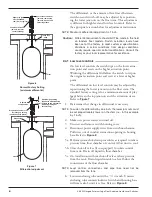

Figure 3

DPDT Terminals for Series HS only

Internal

Circuit

(Right) Switch

1

2

3

Load

Load

Close on low level

Common

Close on high level

Line

4

5

6

Internal Circuit

(Left) Switch

Load

Load

Close on low level

Common

Close on high level

Line