46-605 Flanged External Cage Float Actuated Liquid Level Switches

11

3.0

Troubleshooting

Usually the first indication of improper operation is failure

of the controlled equipment to function, i.e., pump will

not start (or stop); signal lamps fail to light, etc. When

these symptoms occur, whether at time of installation or

during routine service thereafter, check the following

potential external causes first.

✔

Fuses may be blown.

✔

Reset button(s) may need resetting.

✔

Power switch may be open.

✔

Controlled equipment may be faulty.

✔

Wiring leading to control may be defective.

If a thorough inspection of these possible conditions fails

to locate the trouble, proceed next to a check of the

switch mechanism.

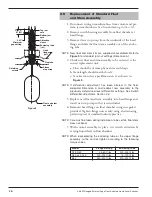

3.1

Check Switch Mechanism

1. Pull switch or otherwise disconnect power to the

control.

2. Remove switch housing cover.

3. Disconnect power wiring from switch assembly.

4. Swing magnet assembly in and out by hand to check care-

fully for any sign of binding. Assembly should require

minimal force to move it through its full swing.

5. If binding exists, magnet may be rubbing enclosing tube.

If magnet is rubbing, loosen magnet clamp screw and shift

magnet position. Retighten magnet clamp screw.

6. If switch magnet assembly swings freely and mechanism

still fails to actuate, check installation of control to be

certain it is within the specified 3° of vertical.

7. Check microswitch continuity with ohmeter. if switch is

damaged, replace immediately.

8. If switch mechanism is operating satisfactorily, proceed to

check sensing unit.

NOTE: As a matter of good practice spare switches should be kept

on hand at all times.

Optional

drain valve

Shutoff valve

(if used)

Conduit

outlet

Switch

actuating level

lreference marks

Shutoff valve

(if used)

Figure 10