IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-20

March 2020

Page 161

IO-390-D Series Engine Maintenance Manual

D.

Solid-Ring Crankshaft Oil Seal Installation

NOTICE:

Install a

new

crankshaft oil seal during crankshaft assembly. There are two types of

crankshaft oil seals: a split oil seal (Figure 47) and the solid-ring stretch oil seal

(Figure 48). The split oil seal is open for easy assembly around the crankshaft. The

solid-ring oil seal has more elasticity and can be stretched over the crankshaft

propeller flange. The solid-ring oil seal can be installed on the crankshaft

before

or

after

the crankshaft is installed in the crankcase. The split oil seal is installed

after

the crankshaft is installed in the crankcase.

Figure 47

Split Oil Seal

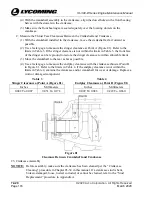

Figure 48

Solid-Ring Oil Seal

NOTICE:

An oversize crankshaft oil seal could be necessary if the crankcase bore size was

increased. Part numbers for oversized parts include a “P” suffix, such as –P10 and

are identified on the face of the seal. Except for the revised outside diameter of the

seals, the oversize seals are identical in other aspects to the standard size seals.

For correct sealing remove all traces of the oil sealant and oil from the crankcase

before a new crankshaft oil seal is installed.

(1)

Solid-Ring Oil Seal Installation

(a)

If not already done, complete the “Starter Ring Gear Support Removal” procedure in

Chapter 72-70.

(b)

Examine the propeller flange, crankshaft sealing surface, and the crankcase seal bore

recess for any scratches or nicks that damage or cause the seal to leak; if found, remove

with fine emery cloth (150 to 220 grit for very light metal sanding) or equivalent small

fine abrasive stone. Remove any residue.

CAUTION

ONLY APPLY MEK SOLVENT TO THE CRANKCASE, INCLUDING

THE CRANKCASE BORE AND GROOVE FOR THE CRANKSHAFT

OIL SEAL. DO NOT APPLY MEK SOLVENT TO THE

CRANKSHAFT OIL SEAL SINCE MEK CAN CAUSE THE SEAL TO

DETERIORATE. BE SURE THAT ALL TRACES OF CLEANING

SOLVENT, OIL AND SEALANT ARE REMOVED PRIOR TO

INSTALLATION OF A NEW CRANKSHAFT OIL SEAL.

(c)

Clean the crankcase bore, use a clean disposable lint-free cloth and any of the following

cleaning solvents to remove oil, sealant, and debris from the crankcase, especially the

crankcase bore which has the groove for the crankshaft oil seal:

•

Methyl-Ethyl-Ketone (MEK)

•

M-17

•

Acetone

•

M-114.

•

Napasco SC-200