IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

12-10

March 2020

Page 77

IO-390-D Series Engine Maintenance Manual

Table 2 (Continued)

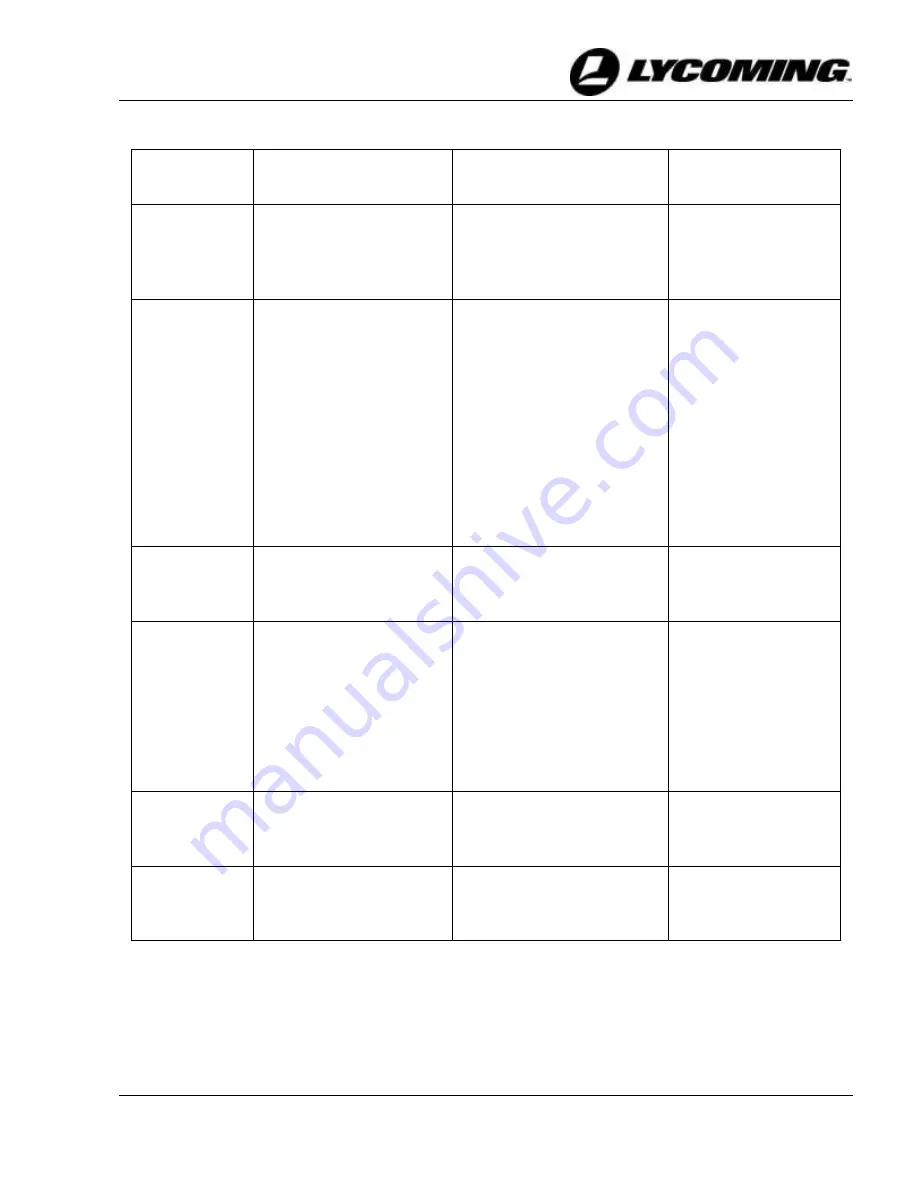

Guidelines for Identification of Metal Particulates and Chips & Corrective Action

Metals/

Alloys

Tests & Characteristics

Possible Source of Origin

on Lycoming Engine

Next Step

Lead

Bearings

If lead chips, chunks,

or balls are found,

complete Corrective

Action 4 in Table 4.

Aluminum

flakes

When placed in 50%

solution of nitric acid

and muriatic acid

(approximately 30%

hydrochloric acid and

water), or a sodium

hydroxide solution, the

aluminum particles

bubble and fizz and form

a black residue

Crankcase

Accessory housing

Oil pump body

Cylinder head

Pistons

Piston pin plugs

Oil sump baffle

Turbocharger inlet housing

Sleeve bearings

Refer to Table 3 for

the quantity and size

of the particles

Magnesium

Oil sump

Refer to Table 3 for

the quantity and size

of the particles

Tin

Soft, malleable

Not picked up by magnet

When dropped onto a

hot (500◦F) soldering

iron, tin particle will

melt and fuse with 50/50

solder

Tin-plated parts

Refer to Table 3 for

the quantity and size

of the particles

Cadmium

Plating

Refer to Table 3 for

the quantity and size

of the particles

Zinc

Plating

Refer to Table 3 for

the quantity and size

of the particles