IO-390-D Series Engine Maintenance Manual

12-30

© 2020 Avco Corporation. All Rights Reserved

Page 96

March 2020

IO-390-D Series Engine Maintenance Manual

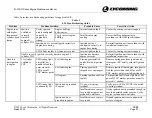

Table 1 (Cont.)

Fault Isolation Guide

Problem

Cause

Corrective Action

Ref.

High oil pressure

Relocated oil pressure

take-off point on the

engine

Use only the approved oil pressure

take-off point.

Oil temperature is too

cold

Before increasing the power control,

allow the oil temperature to increase.

Oil pressure incorrectly

adjusted

Adjust the oil pressure by turning the

pressure adjustment on the oil

pressure relief valve.

72-50

Incorrect weight of oil

used

Use the recommended viscosity of oil

for the ambient temperature per the

latest revision of Service Instruction

No. SI-1014.

Oil passage is blocked

from the pressure relief

valve to the sump

1.

Remove the pressure relief valve

from the engine.

2.

Push a soft copper wire through

the oil passage to the oil sump to

remove blockage.

NOTICE:

If blockage continues,

remove the oil sump and clean the

passage.

72-50

Sluggish propeller

operation

Propeller oil control leak Complete the "Propeller Oil Control

Leak Test Procedure.”

72-20

Engine does not

hold rpm during

cruise, climb, or

descent

Propeller oil control leak Complete the "Propeller Oil Control

Leak Test Procedure.”

72-20

Propeller goes into

feather during

landing rollout with

decreased power

setting

Propeller oil control leak Complete the "Propeller Oil Control

Leak test Procedure.”

72-20