IO-390-D Series Engine Maintenance Manual

72-10

© 2020 Avco Corporation. All Rights Reserved

Page 116

March 2020

IO-390-D Series Engine Maintenance Manual

Engine Assembly Procedure

A.

Complete the sequence of steps in Table 2.

B.

Complete the

Engine Assembly Checklist

in the chapter.

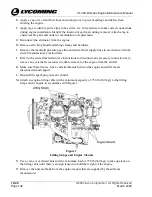

Table 2

Sequence of IO-390-D Series Engine Assembly Procedures

Step

Reference

Step

Reference

Step 1

Review the “General Assembly

Practices” in this chapter

Step 5

Install the

connecting

rods on the

crankshaft

(Figure 4).

“Connecting Rod Installation” procedure

in Chapter 72-20

Begin the “Crankshaft Assembly” procedure in

Chapter 72-20.

Examine the alignment dowel, and if necessary, replace

the alignment dowel.

Step 2

Install the

crankshaft

gear on the

crankshaft

(Figure 1).

“Crankshaft Gear Installation” procedure

in Chapter 72-20

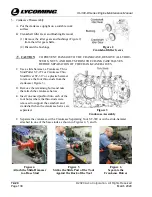

Figure 1

Crankshaft Gear

Figure 4

Connecting Rods

Step 6

“Counterweight Installation” procedure

in Chapter 72-20

Figure 5

Counterweights

Step 3

Install the

expansion

plug on the

crankshaft

(Figure 2).

“Expansion Plug Installation” procedure

in Chapter 72-20

Figure 2

Expansion Plug

Install the

counter-

weights on

the

crankshaft

(Figure 5).

Step 4

Start install-

ation of the

solid-ring

crankshaft

oil seal on

the

crankshaft

(Figure 3).

(or install

the oil seal

later on)

“Solid-Ring Crankshaft Oil Seal

Installation” procedure in Chapter 72-20

Figure 3

Solid-Ring Crankshaft Oil Seal

Step 7

Install the

piston

cooling

nozzle (if

removed)

(Figure 6).

“Piston Cooling Nozzle Installation (if

removed)” procedure in Chapter 72-20

Figure 6

Piston Cooling Nozzles

NOTICE:

In this chapter the term “magneto” can refer to either the Lycoming Electronic Ignition

System (EIS) or optional, traditional magnetos, depending on the type of system

installed on the engine.