THE HYDRAULICS SYSTEM MAY HAVE “TRAPPED” HIGH-

PRESSURES EVEN WHEN DIESEL IS OFF. ALWAYS RELIEVE

THESE TRAPPED PRESSURES BY RATTLING THE CONTROL

LEVERS ABOUT THEIR CENTERED-NEUTRAL POSITIONS

(WITH THE DIESEL SHUTDOWN) BEFORE LOOSENING ANY

SYSTEM CONNECTIONS.

SOME MACHINE COMPONENTS COULD HAVE GRAVITY

PULLING ON THEM AS THEY ARE HYDRAULICALLY HELD IN

PLACE. ALWAYS STOP AND THINK FIRST IF A BLADE OR

OTHER MACHINE COMPONENT NEEDS TO BE REPOSITIONED

TO ITS “DEAD END” (OR OTHER POSITION) SO IT WILL NOT

MOVE BY GRAVITY WHEN A HYDRAULIC CONNECTION IS

LOOSENED FOR REPAIR.

THE HYDRAULIC CYLINDERS COULD BE HOLDING A

PARTICULAR COMPONENT (SUCH AS A “BLADE”) IN A

PARTICULAR POSITION WHEN THE DIESEL IS OFF. AN

EXAMPLE OF THIS IS WOULD BE THE SLIDER BLADE HELD

UPWARD IN ITS “HOME” POSITION BY THE OIL “LOCKED”

INSIDE ITS CYLINDERS WITH DIESEL OFF. IF A HYDRAULIC

HOSE OR FITTING IS THEN WORKED-ON, GRAVITY

WILL

MOVE THE COMPONENT TO A NEW POSTION IN A

UNCONTROLABLE FASHION. FAILURE TO ACCOUNT FOR THIS

FACT COULD RESULT IN SERIOUS INJURY OR DEATH.

OFTEN YOU CAN PURPOSEFULLY MOVE THE COMPONENT TO A

POSITON WHERE GRAVITY CAN NOT MOVE IT

BEFORE

WORKING ON THE HYDRAULICS.

SOMETIMES YOU WILL NEED TO SECURE THE COMPONENT IN

PLACE BY WELDING TEMPORARY STEEL “BLOCKING” OR

“STOPS” ONTO THE PACKER.

CALL LOADMASTER IF YOU HAVE ANY DOUBTS ABOUT THE

CORRECT AND SAFEST METHODS OF DOING THIS.

HYDRAULIC HOSES AND TUBING MUST BE INSPECTED ON A

DAILY BASIS FOR LEAKS, CUTS, ABRASIONS, DAMAGE,

RUBBING (NO CLEARANCE IN ROUTING), BEFORE THE TRUCK

IS PUT IN SERVICE. IF YOUR INSPECTION DISCOVERS SUCH

ADVERSE

CONDITIONS,

THE

SITUATION

MUST

BE

CORRECTED BEFORE TRUCK CAN BE PLACED IN SERVICE.

LOADMASTER RECOMMENDS YOU REPLACE

ALL OF YOUR

RUBBER HOSES AND THE CLAMPING AT LEAST EVERY THREE

YEARS.

FAILURE TO CLOSELY INSPECT AND MAINTAIN YOUR LEGACY

AND CHASSIS COULD LEAD TO SERIOUS INJURY.

NEVER OPERATE THE HYDRAULIC SYSTEM IF ANY LEAK IS

PRESENT. SERIOUS INJURY MAY RESULT.

ALL OF THE LEGACY3’S PRESSURE GUAGE READINGS ARE TO

BE TAKEN AT THE GAUGE STEM LOCATED AT THE INLET

COVER OF THE BODY-MOUNTED VALVE! USE A GLYCERIN

FILLED GUAGE ON THE END OF A 24” HOSE (1/4” DIAMETER

WITH 3000 PSI WORKING PRESSURE RATING) THAT ALLOWS

YOU TO BE FULLY OUTSIDE THE BODY WITH BOTH FEET ON

GROUND AND THEN TAKE THE GAUGE READING. DIESEL

MUST BE SHUTDOWN AND KEYS IN YOUR POCKET BEFORE

ENTERING THE BODY THROUGH THE ACCESS DOOR TO

COUPLE THE GAUGE COUPLER.

NEVER ATTEMPT TO READ A GLYCERIN-FILLED GAUGE WHICH IS

ATTACHED TO THE INLET COVER OF THE

TAILGATE-MOUNTED

VALVE. ALWAYS COUPLE YOUR GLYCERIN FILLED GAUGE TO THE

BODY-MOUNTED VALVE’S GUAGE STEM. ALL LOADMASTER PRESSURE

SPECS ARE CHECKED/ADJUSTED AT THE BODY-MOUNTED VALVE’S

GAUGE STEM.

Sec01-pg06

Содержание LEGACY 3 Series

Страница 13: ...Sec02 pg04 1 2 3 5 6 6 7 9 17 16 18 20 21 8 11 15 19...

Страница 17: ...Sec02 pg08 1 5 8 7 9 6 13...

Страница 19: ...sec02 pg10 1 2 3 4 9 10 12 14...

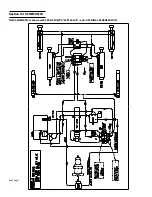

Страница 24: ...Section 03 SCHEMATICS THIS SCHEMATIC is shown with FRONT PUMP S WET VALVE and OPTIONAL REGENERATION Sec03 pg01...

Страница 25: ...Sec03 pg02...