FOLLOW ALL LOCKOUT/TAGOUT PROCEDURES AS DEFINED

IN THIS MANUAL, AS WELL AS WELL AS DEFINED BY YOUR

SPECIFIC SHOP (EMPLOYER) AND OSHA! FAILURE TO HEED

THIS WARNING OF DANGER MAY RESULT IN SERIOUS

PERSONAL INJURY OR DEATH.

YOU MUST NOT SERVICE, MAINTAIN, OR REPAIR THE LEGACY

UNLESS:

YOU ARE QUALIFIED BY TRAINING AND EXPERIENCE IN THE

SAFE

OPERATION OF THIS MACHINE.

TRAINING INCLUDES COMPLETE KNOWLEDGE OF YOUR

EMPLOYER’S

WORK

RULES,

ALL

GOVERMENTAL

REGULATIONS, AND MANUFACTURER’S OPERATOR’S MANUAL

RELATIVE TO THIS MACHINE’S SAFE USE

.

A SERVICE TECHNICIAN WHO IS UNTRAINED IN THE SAFE

OPERATION OF THE LEGACY SUBJECTS HIMSELF/HERSELF

AND OTHERS TO SERIOUS INJURY OR DEATH.

YOU MUST NOT SERVICE, MAINTAIN, OR REPAIR THE LEGACY

UNLESS YOU ARE THOROUGHLY KNOWLEDGEABLE OF YOUR

SHOP’S (YOUR EMPLOYER’S) DETAILED LOCKOUT/TAGOUT

POLICIES AND PROCEDURES.

LOADMASTER HAS INCLUDED THE OUTLINE OF A SKELETON,

BARE BONES LOCKOUT/TAGOUT PROCEDURE IN THIS

MANUAL (SEE TABLE OF CONTENTS). IT IS THE

RESPONSIBILITY

OF

THE

OWNERS,

SUPERVISORS,

MAINTAINERS, AND OPERATORS OF THE LEGACY3 TO FULLY

DEVELOP A “DETAILED” LOCKOUT/TAGOUT PROCEDURE AND

POLICY

THAT

SUITS

YOUR

SHOP’S

SPECIFIC

CIRCUMSTANCES.

NEVER OPERATE, MAINTAIN, OR REPAIR THE VEHICLE OR

THE LEGACY WHILE UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS! WORKERS UNDER THE INFLUENCE PRESENT A

HAZARD TO THEMSELVES AND OTHERS AND CAN CAUSE

SERIOUS INJURY OR DEATH.

DO NOT OPERATE, MAINTAIN, OR REPAIR THE VEHICLE OR

THE LEGACY UNLESS YOU ARE ALERT, CLEAR-HEADED AND

WELL RESTED. IF YOU ARE FEELING TIRED, DO OTHER WORK

CHORES THAT DO

NOT REQUIRE YOU TO BE NEAR A

HYDRAULICALLY-POWERED MACHINE.

DO NOT WEAR WATCHES, RINGS, AND JEWELRY WHILE

WORKING WITH MECHANICAL OR ELECTRICAL EQUIPMENT.

DO NOT WEAR LOOSE CLOTHING THAT COULD ENTAGLE YOU

INTO MOVING OR ROTATING COMPONENTS. THESE TYPES

OF THINGS WILL BE HAZARDOUS AND COULD CAUSE

SERIOUS INJURY OR DEATH IF WORN NEAR MOVING

MECHANICAL OR HYDRAULIC MACHINE PARTS.

DO WEAR PERSONAL PROTECTION ITEMS SUCH AS HARD

HATS, SAFETY GLASSES (EYE PROTECTION), HEAVY GLOVING,

AND SAFETY SHOES WHEN OPERATING OR MAINTAINING

THE LEGACY OR CHASSIS. OPERATORS SHOULD WEAR

VESTING THAT HAS A BRIGHT COLORATION (ORANGE) AND

REFLECTIVE CHARACTERISTICS FOR DAY/NIGHT VISIBILITY.

FOLLOW ALL OF YOUR EMPLOYER’S REQUIREMENTS FOR

PERSONAL PROTECTIVE ITEMS.

[sec02-pg02]

Содержание LEGACY 3 Series

Страница 13: ...Sec02 pg04 1 2 3 5 6 6 7 9 17 16 18 20 21 8 11 15 19...

Страница 17: ...Sec02 pg08 1 5 8 7 9 6 13...

Страница 19: ...sec02 pg10 1 2 3 4 9 10 12 14...

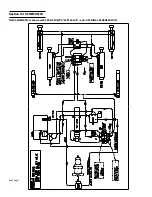

Страница 24: ...Section 03 SCHEMATICS THIS SCHEMATIC is shown with FRONT PUMP S WET VALVE and OPTIONAL REGENERATION Sec03 pg01...

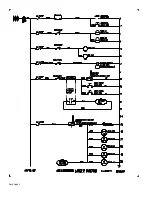

Страница 25: ...Sec03 pg02...