2

CHECK THE OIL TANK’S FILL LEVEL…DAILY

The tank has a sight level gauge that is used to confirm

the correct amount of hydraulic fluid is in the system.

Checking procedure:

1-

Retract the ejector blade fully forward towards cab.

2-

Tailgate fully lowered closed and latched.

3-

The slider cylinders must be fully retracted (slider fully up)

and sweep cylinders fully retracted (sweep rotated up).

4-

PTO disengaged (diesel can be on or off).

5-

Now read the tank’s fill level gauge. The amber colored

hydraulic oil’s level should be visible

6-

Fill to the upper black line (with all cylinders retracted).

DO NOT

OVERFILL

THE TANK. Oil will spray out of the

tank’s filler/breather if overfilled.

Be certain to position the ejector, tailgate, and compact

blades are as described above

before

sighting the

gauge. This will position the “cylinders” to assure you do

not overfill.

Use a name brand hydraulic fluid in an AW46 grade

whenever you add fluid.

3

CHECK THAT THE SUCTION LINE VALVE (GATE

VALVE) IS FULLY OPEN…DAILY

The leverarm of the full-port ball valve must be “parallel”

to its body to be fully open

4

CHECK

THE

“PLUMBING”

FOR

EXTERNAL

LEAKS…DAILY

Hydraulic fluid is flammable and messy. When fluid is on

the shop floor or on the LEGACY3 it can cause injuries

from slipping and falling. Inspect the LEGACY3’s various

fittings, hoses, tubes for any evidence of oil escaping.

Often by retorquing the hose end or fitting you can stop

the leakage. Sometimes a hose or fitting will need to be

replaced.

5

CHECK THE PUMP AND VALVES FOR EXTERNAL

LEAKAGE…DAILY

The LEGACY3 uses “0-ring boss” ports on all the valve

ports and the pump. Leakage here is usually going to be

correctable by retightening the attached fittings. In

some rare cases the o-ring may be nicked or extruded,

replace the o-ring or install fresh fitting. The valves have

a group of o-rings seals between their cast sections. If

oil seems to be weeping out between sections, try to re-

torque (evenly) the valve tie-rod bolts first (loosen

valve’s mounting foot bolts first). The pump has a seal

on its input shaft that could eventually weep oil. This

must be replaced if this is happening.

The most difficult job in fixing a leak is identifying where

the oil is

really

escaping. Gravity, road travel blow-age,

etc can fool you into misidentifying. If in doubt, wash

area and keep looking until confident.

6

CHECK THE ROD CYLINDERS FOR EXTERNAL

LEAKAGE…DAILY

Rod cylinders have a bearing and seal system where the

rod itself leaves the barrel. Repair if leakage occurs

here.

7

INSPECT THE STEEL TUBE RUNS FOR DAMAGE AND

LOOSE CLAMPING…DAILY

If a tube is impacted, it may become damaged. Check

for this. Replace damaged tube so they do not rupture

later.

8

CHECK FOR A FULLY CHARGED, ACCESSIBLE FIRE

EXTINQUISHER…DAILY

Hydraulic fluid is flammable and could ignite if it sprays

upon the diesel’s hot exhaust surfaces.

9

INSPECT THE HOSES FOR ABRASIONS, RUB

SPOTS,ETC…DAILY

Identifying possible hose weaknesses and repairing

them promptly will reduce the possibility of a hose burst

later on.

10

REPLACE

THE

IN-TANK

SUCTION

STRAINER…YEARLY

Near the floor of the oil-tank (submersed) is the suction

filter/strainer. Whenever the tank has been drained of oil

(for whatever reason), remove this filter and replace it

(or clean it if in otherwise good condition). Make sure

the 3-PSI bypass valve is “free” and will fully seat

closed.

[Sec02-pg12]

Содержание LEGACY 3 Series

Страница 13: ...Sec02 pg04 1 2 3 5 6 6 7 9 17 16 18 20 21 8 11 15 19...

Страница 17: ...Sec02 pg08 1 5 8 7 9 6 13...

Страница 19: ...sec02 pg10 1 2 3 4 9 10 12 14...

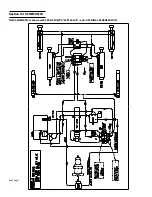

Страница 24: ...Section 03 SCHEMATICS THIS SCHEMATIC is shown with FRONT PUMP S WET VALVE and OPTIONAL REGENERATION Sec03 pg01...

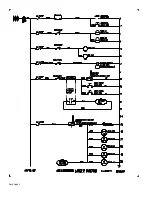

Страница 25: ...Sec03 pg02...