PREVENTIVE MAINTENANCE… THE “SAFETY

SYSTEMS” AND OVERALL UNIT

1

CHECK THE BACKUP ALARM TO BE IN GOOD WORKING CONDITION

WHEN TAILGATE RAISES UPWARD…IT MUST “SOUND” OFF

Check DAILY

2

CHECK THE BACKUP ALARM TO BE IN GOOD WORKING CONDITION

WHEN CHASSIS SHIFTS INTO REVERSE IT MUST SOUND

Check DAILY

3

CHECK THAT THE “SIGNAL BUZZERS” TO BE IN GOOD WORKING

CONDITION; ON BOTH SIDES

Check DAILY

4

CHECK THAT THE SIDE STEPS ARE SECURELY ANCHORED AND

FLAT AND NOT IMPACT DAMAGED

Check DAILY

5

CHECK THAT THE VARIOUS LIGHTS AND SIGNALS NEEDED FOR

SAFE STREET TRAVEL ARE IN GOOD WORKING ORDER

Check DAILY

6

CHECK THAT THE IN-CAB PILOT LITE FOR “TAILGATE RAISED”

IS FUNCTIONING (ILLUMINATING) CORRECTLY

Check DAILY

7

CHECK THAT THE HAND-HOLD GRAB HANDLES ARE SECURELY

ANCHORED

Check DAILY

8

CHECK THAT THE BODY ACCESS DOOR’S LADDER,HINGES, AND

LATCH ARE IN GOOD CONDITION AND FUNCTIONAL

Check DAILY

9

CHECK THAT ALL INFORMATIONAL AND SAFETY RELATED

DECALS ARE IN GOOD, READABLE, AND CLEAN

Check DAILY

10

CHECK FOR ANY HYDRAULIC SYSTEM EXTERNAL LEAKS

HYDRAULIC FLUID IS VERY FLAMMABLE

Check DAILY

11

CHECK THAT THE KNOBBED CONTROLS MOVE FREELY AND

RETURN TO THEIR “NEUTRAL” POSITION FREELY

Check DAILY

12

CHECK THE PACKER AND THE TRUCK CHASSIS TO BE CLEAN AND

FREE OF DEBRIS (PRESSURE WASH ONCE A MONTH)

Check/wash at least MONTHLY

13

CHECK THAT THE IN-CAB “PTO ENGAGED” PILOT LITE BECOMES

ILLUMINTATED WHEN PTO IS ENGAGED.

Check DAILY

14

15

CHECK THAT THE SUCTION LINE “GATE” VALVE IS FULLY OPEN

Check DAILY

16

CHECK THE CONDITION OF THE RETURN LINE FILTER

Check WEEKLY

17

CHECK THE CONDITION OF THE TAILGATE’S MAIN PIVOT

HINGE…CHECK THE PINNINGS AND PIN RETENTIONS

Check MONTHLY

18

CHECK THE CONDITION OF THE TAILGATE LIFT CYLINDERS’ PINS

(4), AND PINNINGS AND PIN RETAINERS (BOLTS AND/OR COTTER

PINS

Check MONTHLY

19

CHECK THE WEAR PATTERN OF THE SLIDE BLADES SLIDER

SHOEING

Check MONTHLY

20

CHECK THE CONDITION OF THE BODY-T0-CHASSIS MOUNTING

PLATES, HARDWARE, SPRINGS

Check MONTHLY

21

CHECK THE EJECTOR BLADE’S SHOEING FOR WEAR

Check EVERY 6 MONTHS

IF UNIT IS EQUIPPED WITH ANY OPTIONAL “CONTAINER

LIFTING” MECHANISMS (SUCH AS THE OPTIONAL “2-10” ROOF

MOUNTED REEVER) INVOLVING “CABLES”…THEN:

22

CHECK EACH CABLES “3-CLIP” ANCHORING TO BE SECURE

AND IN GOOD CONDITION (ON THE BODY ROOF)

Check WEEKLY

23

CHECK THE CONDITION OF THE CABLE ITSELF

Check WEEKLY

24

CHECK THAT THE CABLE PROTECTING “THIMBLE” IS IN PLACE

AND PARTICULARY CHECK THAT CABLE IS IN GOOD CONDITION AT

THE ANCHORING “THIMBLE” AREA

Check WEEKLY

25

CHECK ALL THE PINNINGS, SHEAVE AXLES, ETC ARE ALL

SECURLEY “RETAINED” AND IN GOOD CONDITION

Check WEEKLY

[Sec02-pg03]

“PTO ENGAGED”

LIGHT …13

Содержание LEGACY 3 Series

Страница 13: ...Sec02 pg04 1 2 3 5 6 6 7 9 17 16 18 20 21 8 11 15 19...

Страница 17: ...Sec02 pg08 1 5 8 7 9 6 13...

Страница 19: ...sec02 pg10 1 2 3 4 9 10 12 14...

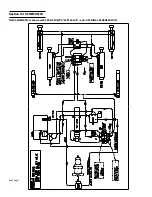

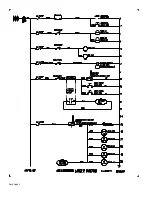

Страница 24: ...Section 03 SCHEMATICS THIS SCHEMATIC is shown with FRONT PUMP S WET VALVE and OPTIONAL REGENERATION Sec03 pg01...

Страница 25: ...Sec03 pg02...