2.

R

emove liner assembl

y

.

(

See

M

aintenance

Section

)

3

.

R

emove gun tube assembl

y

.

(

See

M

aintenance

Section

)

4.

R

emove wire drive assembl

y

.

(

See

M

aintenance

Section

)

5. Disconnect trigger. Use ad

j

ustable

p

liers to

remove cable strain relie

f

f

rom right handle hal

f

.

(

See

f

igure D.1

3)

FIGURE D.13

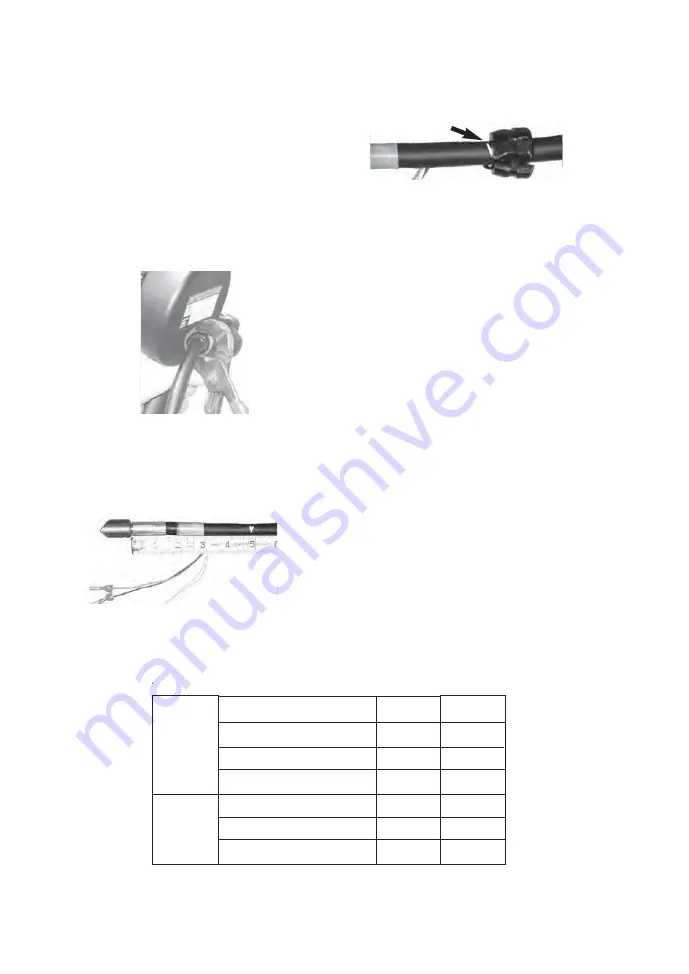

6. Pull damaged cable out o

f

the right handle hal

f

.

The cable connector will

f

it through the strain relie

f

o

p

ening.

M

ark the new cable at a

p

oint 4.750 to

4.81

3

inches

f

rom the end o

f

the cable connector.

(

See

f

igure D.14

)

FIGURE D.14

7. Place the strain relie

f

onto the new cable at the

mark as shown in

f

igure D.15.

MAINTENANCE

D-5

FIGURE D.15

8. Install the new gun cable. Pass the cable connec-

tor through the o

p

ening in the right handle, seat

the strain relie

f

in

p

lace, and then check to insure

the cable is not kinked between strain relie

f

and

connector.

R

eassemble gun b

y

reversing ste

p

s 2

through 5.

CORRECTING WIRE SHAVING ISSUES

1. I

f

the inlet o

f

the liner assembl

y

is shaving the alu-

minum wire

(

the wire is usuall

y

p

eeled o

ff

in curled

chi

p

s

)

during

f

eeding, the wire

f

eed centerlines o

f

the wire drive and the liner itsel

f

ma

y

be mis-

aligned.

• This misalignment ma

y

occur whenever the gun

tube, wire drive, or welding cable assemblies are

re

p

laced.

• A limited amount o

f

ad

j

ustment is available at the

gun tube mounting to

p

ossibl

y

eliminate the shav-

ing

p

roblem.

2. Visuall

y

check i

f

wire is centered in the liner

ʼ

s inlet

o

p

ening. Feed wire through the s

p

ool gun and note

which side the shaving seems to occur.

3

.

R

emove le

f

t side o

f

handle. See Figure D.10

G

un

Tube

R

e

p

lacement. Slightl

y

loosen gun tube

ʼ

s nut

as shown.

4. Slide the gun tube in the mounting

p

late

ʼ

s hole to

realign the wire and then retighten the nut as

shown.

R

eassemble the gun.

5.

R

e

p

eat ste

p

s 2 thru 4 until shaving is eliminated. A

light accumulation o

f

f

ine dust is also

p

ermissible

a

f

ter

f

eeding 1/4 o

f

a s

p

ool during welding use.

Consumable

parts

Periodic

replacement

parts

Contact tip, 0.030 wire (S19726-2)

Contact tip, 0.035 wire (S19726-3)

Gas diffuser (S19728)

Gas cone assembly (M16294)

Gun tube assembly (S19703-1)

Drive roll assembly (S26236-2)

Liner assembly (S26612)

KP2039-2B1

KP2039-3B1

KP2040-1

KP1938-1

KP2631-1

KP2529-2

KP2632-1

10-pack

10-pack

1-piece

1-piece

1-piece

1-piece

1-piece

TABLE D.2

Consumable

parts

Periodic

replacement

parts

Contact tip, 0.030 wire (S19726-2)

Contact tip, 0.035 wire (S19726-3)

Gas diffuser (S19728)

Gas cone assembly (M16294)

Gun tube assembly (S19703-1)

Drive roll assembly (S26236-2)

Liner assembly (S26612)

KP2039-2B1

KP2039-3B1

KP2040-1

KP1938-1

KP2631-1

KP2529-2

KP2632-1

10-pack

10-pack

1-piece

1-piece

1-piece

1-piece

1-piece

TABLE D.2

M

ark

f

or strain relie

f

Содержание K2532-1

Страница 3: ......

Страница 4: ......

Страница 22: ...NOTES MAGNUM 100SG...

Страница 36: ...MAGNUM 100SG NOTES...

Страница 41: ......

Страница 58: ...NOTAS MAGNUM 100SG...

Страница 72: ...MAGNUM 100SG NOTES NOTAS...

Страница 75: ......

Страница 76: ......

Страница 94: ...NOTES MAGNUM 100SG...

Страница 108: ...MAGNUM 100SG NOTES MAGNUM 100SG NOTES...

Страница 109: ...NOTES NOTAS MAGNUM 100SG...

Страница 115: ...NOTES NOTAS MAGNUM 100SG...