MAINTENANCE

D-4

4. Obtain a new re

p

lacement gun tube

(

i

f

need-

ed

)

.

R

emove locking nut

f

rom old gun tube and

install onto new gun tube.

N

ut should be

f

ull

y

threaded

f

inger-tight against the insulating

tube.

5. Slide gun tube

ʼ

s external threads through gun

tube mounting

p

late and screw the gun tube b

y

hand into the cable connector until the nut

p

ulls

the mounting

p

late snug against the connector.

6. Tighten the nut and mounting

p

late to the con-

nector with Tor

q

ue Wrench 10 to 12

f

t.-lbs.

7.

R

eassemble gun. Be care

f

ul not to

p

inch an

y

leads between gun handle halves.

WIRE DRIVE ASSEMBLY REMOVAL AND

INSTALLATION

1. There are no serviceable or maintainable

p

arts

inside o

f

the wire drive.

2.

R

emove liner assembl

y

(

See

M

aintenance

Section

f

igures D.2 and D.

3)

.

3

.

R

emove le

f

t side o

f

handle.

4. Disconnect black and red leads

f

rom drive

motor. Use care to

p

revent damage to motor

ʼ

s

f

ast-on electrical tabs.

5. Slide wire drive out o

f

right handle hal

f

.

6. When reinstalling wire drive, note the

p

ro

p

er

motor lead connection in the

f

igure.

R

econnect

red motor lead to

p

ositive

(

+

)

terminal, marked

with red dot at arrow.

R

econnect black lead to

other motor terminal.

(

See

f

igure D.11

)

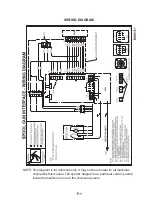

FIGURE D.11

7.

R

eassemble gun. Be care

f

ul not to

p

inch an

y

leads between gun handle halves.

TRIGGER ASSEMBLY REPLACEMENT

1. There are no serviceable or maintainable

p

arts

inside o

f

the trigger.

2.

R

emove s

p

ool cover and le

f

t side o

f

handle.

3

. Slide trigger out o

f

right handle hal

f

. Disconnect

both white leads

f

rom trigger. Use care to

p

re-

vent damage to electrical leads and the termi-

nals.

(

See Figure D.12

)

FIGURE D.12

4. Connect both white leads to the new trigger.

Either lead ma

y

be connected to either trigger

p

in

(

non-

p

olari

z

ed connections

)

.

5. Slide new trigger into

p

lace and reassemble the

gun. Be care

f

ul not to

p

inch an

y

leads between

gun handle halves.

WELDING CABLE ASSEMBLY

REPLACEMENT

1.

G

enerall

y

, there are no serviceable or maintain-

able

p

arts, exce

p

t

f

or both o-rings on the

machine

ʼ

s

p

ower and gas connector; these

seals ma

y

be re

p

laced. However, there are

o

p

tions:

• Damage to the

f

our #22 AW

G

control leads at

the gun cable

ʼ

s welding machine end

(

P6

p

lug

)

ma

y

be re

p

airable without

removing or

re

p

lacing the entire gun cable. The leads

can be s

p

liced and soldered back togeth-

er, and then reinsulated with heat-shrink

tubing. See Table D.1 in

M

aintenance

Section

f

or a descri

p

tion o

f

the connec-

tions.

• Otherwise, the damaged gun cable ma

y

be re

p

laced.

White Leads

“

+

”

Terminal

R

ed Dot

Black Lead

Содержание K2532-1

Страница 3: ......

Страница 4: ......

Страница 22: ...NOTES MAGNUM 100SG...

Страница 36: ...MAGNUM 100SG NOTES...

Страница 41: ......

Страница 58: ...NOTAS MAGNUM 100SG...

Страница 72: ...MAGNUM 100SG NOTES NOTAS...

Страница 75: ......

Страница 76: ......

Страница 94: ...NOTES MAGNUM 100SG...

Страница 108: ...MAGNUM 100SG NOTES MAGNUM 100SG NOTES...

Страница 109: ...NOTES NOTAS MAGNUM 100SG...

Страница 115: ...NOTES NOTAS MAGNUM 100SG...