Diagnostic information

2-27

7526

Go Back

Previous

Next

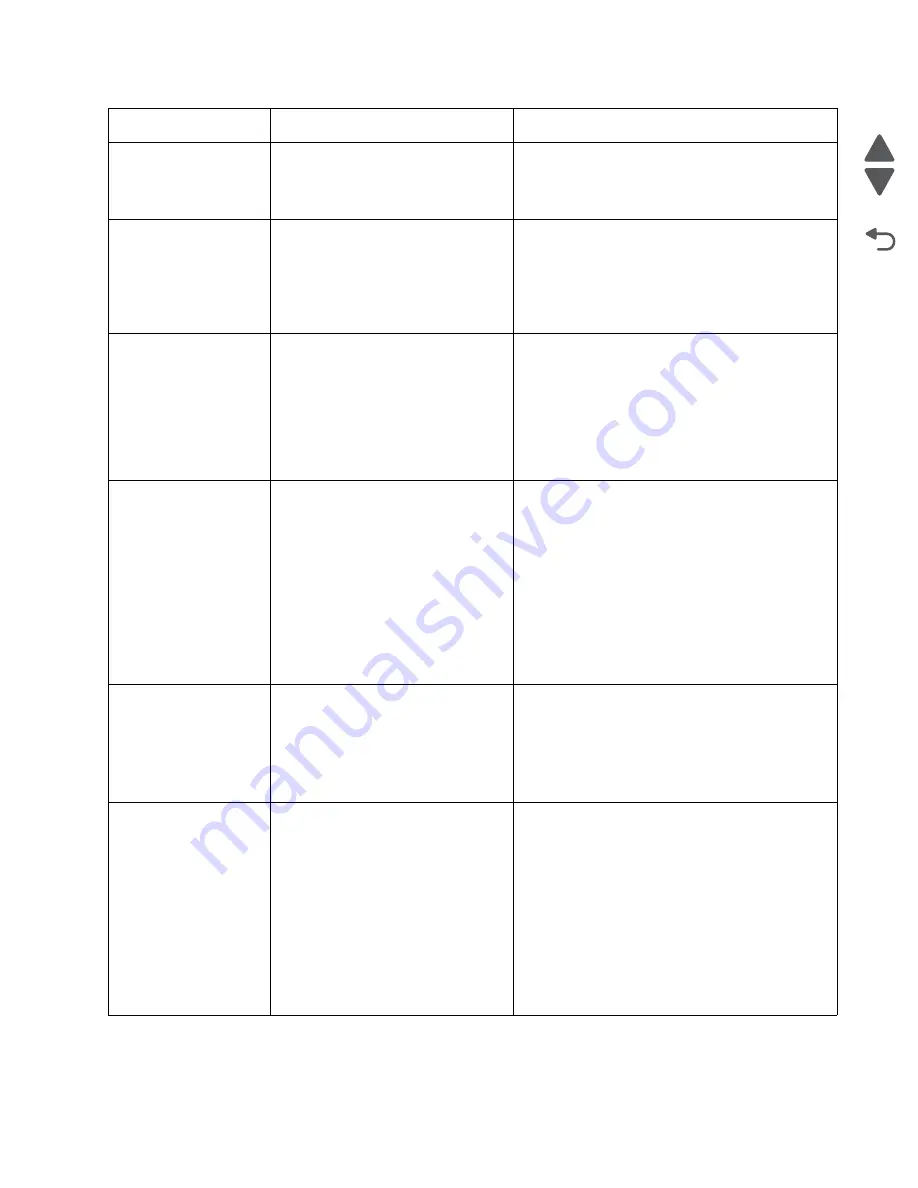

242.29

Tray 2 is not ready or missing while

printing.

Possible cause is paper tray 2

assembly failure:

• Make sure that tray 2 is correctly inserted.

• If the problem persists, go to

Jam service check” on page 2-78

243.02

Tray 3 pass thru sensor made at

POR.

Possible causes:

• Paper jam leaving page over the

sensor

• Defective pass thru sensor

• Check for anything in the paper path that might

cause the paper to jam.

• If clearing a paper jam does not fix the problem,

“243.02—Paper Jam service check” on

243.03

Pick timeout from tray 3 exceeded

without a tray 3 sensor break.

Possible causes:

• Tray 3 incorrect media setting

• Tray 3 incorrect paper loading

• Tray 3 incorrect media restraint

setting

• Tray 3 assembly failure

• Remove all media present in the paper path.

• Ensure proper media is set for the type of paper

used in tray 3.

• Fan media, and stack flat in tray 3.

• Properly set media restraints in tray 3.

• If the previous actions do not fix the problem, go

to

“243.03, 243.11—Paper Jam service

243.05

Tray 3 picked, but page failed to reach

the option sensor in time.

Possible causes:

• Tray 3 incorrect media setting

• Tray 3 incorrect paper loading

• Tray 3 incorrect media restraint

setting

• Tray 3 paper pick mechanism

failure

• Loading card stock from the

special media tray above the till

line.

• Ensure proper media is set for the type of paper

used in tray 3.

• Fan media, and stack flat in tray 3.

• Properly set the media restraints in tray 3.

• Check the pick tires in tray 3 and replace if worn.

• If the previous actions do not fix the problem, go

to

“243.05—Paper Jam service check” on

243.10

Tray 3 page exits pass thru sensor

broken early.

Possible causes:

• Defective pass thru sensor

• Faulty cable in connector OPT1

• Make sure the proper media is set for the type of

paper used in tray 3.

• Check for anything in the paper path that might

cause the paper to jam.

• The exit pass thru sensor may not be

functioning properly. Go to

Jam service check” on page 2-81

243.11

Tray 3 sensor never broke.

Possible causes:

• Incorrect tray 3 media setting

• Incorrect tray 3 paper loading

• Incorrect media restraint setting

• Paper tray failure

• Aligner failure

• Transport belt module failure

• Loading card stock from the

special media tray above the fill

line.

• High humidity (replace paper)

• Ensure the proper media is set for the type of

paper used in tray 3.

• Fan media, and then stack flat in tray 3.

• Properly set the media restraints in tray 3.

• Check the pick tires in tray 3 and replace if worn.

• If the problem persists, Go to

Paper Jam service check” on page 2-79

.

Error code

Description

Action

Содержание X734DE

Страница 10: ...x Service Manual 7526 Go Back Previous Next...

Страница 15: ...Notices and safety information xv 7526 Go Back Previous Next...

Страница 16: ...xvi Service Manual 7526 Go Back Previous Next...

Страница 22: ...xxii Service Manual 7526 Go Back Previous Next...

Страница 254: ...3 58 Service Manual 7526 Go Back Previous Next Printer base...

Страница 266: ...3 70 Service Manual 7526 Go Back Previous Next...

Страница 277: ...Repair information 4 11 7526 Go Back Previous Next d Touch Quick Test A page similar to this one prints...

Страница 293: ...Repair information 4 27 7526 Go Back Previous Next 4 Remove the five larger screws B and the two smaller screws C...

Страница 300: ...4 34 Service Manual 7526 Go Back Previous Next 4 Remove the five larger screws B and the two smaller screws C...

Страница 316: ...4 50 Service Manual 7526 Go Back Previous Next 7 Remove the six screws G 8 Remove the screw H in front...

Страница 324: ...4 58 Service Manual 7526 Go Back Previous Next 6 Grasp the auger shaft C and remove it C...

Страница 328: ...4 62 Service Manual 7526 Go Back Previous Next 5 Remove the two screws C 6 Remove the cartridge cooling fan C...

Страница 359: ...Repair information 4 93 7526 Go Back Previous Next 14 Remove the two screws O on the inside O P...

Страница 360: ...4 94 Service Manual 7526 Go Back Previous Next 15 Remove the seven screws R securing the EP drive R R First R R...

Страница 398: ...4 132 Service Manual 7526 Go Back Previous Next 3 Insert the motor into the frame 4 Replace the screws C...

Страница 422: ...4 156 Service Manual 7526 Go Back Previous Next f Touch Quick Test A page similar to this one prints...

Страница 464: ...4 198 Service Manual 7526 Go Back Previous Next 4 Remove the five larger screws B and the two smaller screws C...

Страница 482: ...4 216 Service Manual 7526 Go Back Previous Next 9 Remove the two screws G G 18B1236...

Страница 495: ...Repair information 4 229 7526 Go Back Previous Next 5 Lift the cover from the ADF...

Страница 513: ...Repair information 4 247 7526 Go Back Previous Next 5 Grasp the cover on the lower right and pull up...

Страница 571: ...Connector locations 5 1 7526 Go Back Previous Next 5 Connector locations Locations printer base...

Страница 572: ...5 2 Service Manual 7526 Go Back Previous Next Connectors System board...

Страница 582: ...5 12 Service Manual 7526 Go Back Previous Next...

Страница 588: ...6 6 Service Manual 7526 Go Back Previous Next...

Страница 592: ...7 4 Service Manual 7526 Go Back Previous Next Assembly 2 Front 5 2 3 4 7 9 11 A B D 8 10 12 E 13 C G F F 1 6...

Страница 594: ...7 6 Service Manual 7526 Go Back Previous Next Assembly 3 Right 1 2 3 4 5 6...

Страница 596: ...7 8 Service Manual 7526 Go Back Previous Next Assembly 4 Rear...

Страница 602: ...7 14 Service Manual 7526 Go Back Previous Next Assembly 8 Covers scanner 6 8 9 10 5 7 11 14 1 2 13 3 4 12...

Страница 604: ...7 16 Service Manual 7526 Go Back Previous Next Assembly 9 Automatic document feeder ADF...

Страница 606: ...7 18 Service Manual 7526 Go Back Previous Next Assembly 10 Flatbed scanner...

Страница 612: ...7 24 Service Manual 7526 Go Back Previous Next Assembly 14 Options and features...

Страница 614: ...7 26 Service Manual 7526 Go Back Previous Next...

Страница 622: ...I 8 Service Manual 7526 Go Back Previous Next...

Страница 626: ...I 12 Service Manual 7526 Go Back Previous Next...