18 Safety

Do not attach the hook to any lift point which will

not be completely encircled by the hook with

the safety latch closed. Do not remove the hook safety

latch.

Read and obey all container decals issued by the container manufacturer.

Read and follow container manufacturer’s information on accepted use practices.

Do not attempt to lift overloaded containers.

Center the container on the attachment.

All containers should be inspected for serviceability and repaired if not in safe, usable condition.

Do not use non-standard or damaged trunnion bar.

Never cross under a raised container.

Stand clear when dumping containers.

Before attempting to lift a container below 32 °F (0 °C), make sure it is not frozen to the ground.

When using an eye type container attachment point, the base of the hook must be positioned to

lift on the inside of the eye.

Place the container on a flat, level surface.

Do not get into the hopper compartment or try to repair anything on the packer when it is moving

or when the hydraulic pump is still running. Personnel authorized to get into the hopper

must

first

lock out and tag out the vehicle, as required by the employer. For more information, see

Out and Tagging Out the Vehicle

Hydraulics

Hydraulic fluid operates under high temperatures. Avoid

contact with piping, hoses or cylinders

to prevent burns.

Never use hands to check for leaks. Hydraulic fluid escaping under pressure may cause injury.

In case of injury seek proper medical treatment immediately.

Fire Protection

Anytime a loaded vehicle is

brought inside a garage,

fire extinguishers shall be close at hand.

The employer must inform employees of an appropriate place to unload the body near the

maintenance facility (preferably away from traffic, surface drains, and ditches).

Keep a fire extinguisher accessible at all times

.

Never use lighted smoking materials, open flame or sparks around when working with flammable

materials such as fuel tanks or storage batteries.

Never have an open flame as a light source.

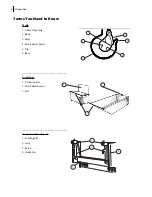

Содержание 2R-III

Страница 1: ...2R III MAINTENANCE MANUAL...

Страница 2: ......

Страница 3: ...2R III MAINTENANCE MANUAL...

Страница 5: ......

Страница 6: ......

Страница 20: ...10 Introduction...

Страница 42: ...32 Safety...

Страница 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Страница 66: ...56 Preventive Maintenance...

Страница 102: ...92 Troubleshooting...