LaserStar

®

Workstation Operation & Maintenance Manual 900 Series Ver. 991.6 November 2019

99

D. Removing the Distilled Water from the Machine for Storage or

Transport

(

Note: Reference the procedure / steps described in section A /

“Initial Filling of the laser Welding System with Distilled Water” with

the following additional steps.)

1. Follow

steps A1 to A10

2. Use a clean siphoning device, hand pump or squeeze pump to remove the

water from the bottle.

3. Re-install the filter into the water bottle.

4. Make up two air hose assemblies (~2 ft in length) for use with a manual air

pump or clean shop air (no water or oil & ≤30 psi): One air hose assembly

with a male garden hose fitting and a second air hose assembly with a female

garden hose fitting. Both air hose assemblies will have fittings on the other

end compatible with the air supply.

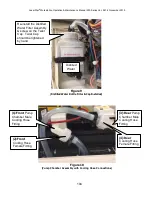

5. Slowly disconnect the “

front

cooling hose female fitting” /

(2)

from the “pump

chamber male cooling hose fitting” /

(1)

as shown in

(Figure 10)

. (

Attention:

Place a paper towel below fitting before loosening to collect any water.)

6. Connect the female garden hose air assembly to the

front

pump chamber

male hose fitting as shown in

(Figure 10)

and blow the air through the cooling

system until there is no water going into the water bottle. (

Note:

This will

remove the water from the pump chamber and the heat exchanger.)

7. Empty the water bottle.

8. Connect the male garden hose air assembly fitting to the

front

cooling hose

female fitting

/ (2)

as shown in

(Figure 10)

9. Blow the air through the cooling system until there is no water going into the

water bottle.

10. Empty the water bottle.

11. Re-connect the

front

cooling hose female fitting /

(2)

to the

front

pump

chamber male cooling hose fitting

/ (1)

.

12. Install the blue filter media; connect the ground wire to the side panel and

install the panel. (

Note:

The side panel is secured with the (6) screws.)

Install the top cover and secure with the (2) screws. (

Note:

Reconnect the

ground wire and make sure the wire does not get pinched when sliding the cover

into position.)

Содержание iWeld 900 Series

Страница 2: ...LaserStar Workstation Operation Maintenance Manual 900 Series Ver 991 6 November 2019 2...

Страница 81: ...LaserStar Workstation Operation Maintenance Manual 900 Series Ver 991 6 November 2019 81 ALARMS Table 1...

Страница 134: ...LaserStar Workstation Operation Maintenance Manual 900 Series Ver 991 6 November 2019 134...

Страница 135: ...LaserStar Workstation Operation Maintenance Manual 900 Series Ver 991 6 November 2019 135 X APPENDIXES...

Страница 136: ...LaserStar Workstation Operation Maintenance Manual 900 Series Ver 991 6 November 2019 136...

Страница 148: ...LaserStar Workstation Operation Maintenance Manual 900 Series Ver 991 6 November 2019 148...

Страница 150: ......

Страница 152: ...LaserStar Workstation Operation Maintenance Manual 900 Series Ver 991 6 November 2019 150...

Страница 153: ......

Страница 154: ......

Страница 155: ......

Страница 156: ......

Страница 157: ......

Страница 158: ......

Страница 159: ......

Страница 160: ......