4-2 MAINTENANCE PROCEDURES

4-2.1

Repair Parts

Repair parts are illustrated and listed in a

separate parts manual. Replacement of parts due

to wear is determined by examination and meas-

urement in the Maintenance Procedures of the

section.

4-2.2

Tool and Equipment

Tools, equipment, and personnel normally

found in a facility capable of making truck repairs

will be adequate for maintenance of the semitrailer.

No other special tools or equipment should be nec-

essary.

4-2.3

Torque Values.

lists torque values for

standard hardware and is intended as a guide for

average applications involving typical stresses and

mechanical surfaces. Values are based on the

physical limitations of clean, plated, and lubricated

hardware. In all cases, when an individual torque

value is specified, it takes priority over values

given in this table. Replace original fasteners with

hardware of equal grade.

4-2.4

Cleaning

WARNING

1. PAINT THINNER AND OTHER SOL-

VENTS ARE FLAMMABLE AND TOXIC

TO EYES, SKIN, AND RESPIRATORY

TRACT. AVOID SKIN AND EYE CON-

TACT. GOOD GENERAL VENTILATION

IS NORMALLY ADEQUATE. KEEP

AWAY FROM OPEN FLAMES OR

OTHER COMBUSTIBLE ITEMS.

2. DO NOT ALLOW ALUMINUM

BRIGHTENER OR OTHER ACID COM-

POUNDS TO CONTACT HYDRAULIC

HOSES. THE HOSE COVERS ARE SUS-

CEPTIBLE TO ACID DETERIORATION.

a.

Wash semitrailer to remove all accumulated

dirt and grime. For washing aluminum use

water and a mild, non-abrasive soap or deter-

gent such as those recommended for auto-

motive finishes; or a non-etching, non-

abrasive aluminum cleaner. Use a soft cloth

or sponge. Rinse with clear water and dry

with a chamois or cloth to prevent spotting or

streaking. Wax with a liquid or paste wax rec-

ommended for the care of automotive fin-

ishes. Wax should be applied every three to

six months or more frequently if exposed to

extreme weather.

b.

Clean the sliding surfaces with solvent or

mineral spirits every six months or more fre-

quently if exposed to extreme dirt or weather

conditions. The slide wear strips are impreg-

nated with a special lubricant, however, addi-

tional lubrication may be required to prevent

chattering or squealing.

See Lubrication

Points and Specifications in Figure 4-1

and Table 4-1

.

c.

After disassembling any components, thor-

oughly clean dirt and old lubricant from all

parts. Do not use a wire brush on any bearing

parts or surfaces — use a stiff bristle brush.

Do not use compressed air, or spin bearing

parts when cleaning. These practices can

throw solvents, dirt, or metal particles into

your eyes. Dry clean parts with lint free,

clean, soft, absorbent, cloth or paper. Wash

and dry hands.

d.

Inspect seals, seal wiping surfaces, bearing

caps, and bearing cones for wear, pitting,

chipping, or other damage.

e.

Use Troubleshooting Guide to check for

“

SYMPTOMS”

AND

“PROBLEMS”

of any

semitrailer system not functioning correctly, or

where wear distortion, or breakage can be

found. Administer

“REMEDY”

according to

right-hand column of Troubleshooting Guide

(See Section 5)

.

f.

Inspect seals, seal wiping surfaces, bearing

caps, and bearing cones for wear, pitting,

chipping, or other damage.

4-4

Содержание 336C

Страница 3: ...MODEL 336C CAR CARRIER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO...

Страница 8: ......

Страница 24: ...3 12 Figure 3 7 Lining Up the Over the Cab Deck Figure 3 8 Loading the Over the Cab Deck...

Страница 28: ...3 16 Figure 3 11 Loading the Lower Deck...

Страница 32: ...3 20 Figure 3 13 Rear Impact Guard and Antilock Brake System...

Страница 40: ...4 6 Figure 4 3 336C Wiring Diagram...

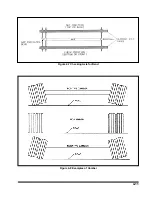

Страница 45: ...4 11 Figure 4 7 Checking Axle for Bend Figure 4 8 Examples of Camber...

Страница 50: ...4 16 Figure 4 12 Axle and Brake Assembly...

Страница 54: ...4 20 Figure 4 14 Outboard Mount Hub and Drum Figure 4 15 Inboard Mount Hub and Drum...

Страница 59: ...4 25 Figure 4 19 Mounting Tires and Wheels Figure 4 20 Stud Tightening Sequence...

Страница 70: ...NOTES 5 10...