3-20 UNLOADING THE 331 OVER-THE-CAB DECK

3-20.1

Lower the front of the semitrailer to the

transport position.

3-20.2

Unlock and lower the middle arm as far

down as it will go.

3-20.3

Unlock and lower the rear arm until the

back edge of the upper deck touches the

lower deck.

3-20.4

Unlock and adjust the front arm so it is

level with the over-the-cab deck.

3-20.5

Put down the wheel stops on the front

of the 336A upper deck.

3-20.6

Slide the over-the-cab deck back to 1/2"

from the 336C upper deck.

3-20.7

Insure that the winch cables are firmly

attached to the vehicles and sufficient ten-

sion is on the cables so load securing chains

can be safely removed.

3-20.8

Reel out winch #1

(See Figure 3-6)

to

allow the vehicle to move off of the Over-

the-cab deck and onto the trailer upper deck.

3-20.9

After the vehicle is completely on the

trailer bed, secure the vehicle so winch #1

(See Figure 3-6)

can be disconnected and

winch #2

(See Figure 3-6)

can be connected

to the vehicle.

3-20.10

Secure winch #1 cable to the over-

the-cab deck.

3-20.11

Slide the over-the-cab deck forward to

transport position.

3-20.12

Follow the procedure for unloading the

trailer upper deck.

3-20.13

Prepare trailer for transport.

3-20.14

Disengage the P.T.O. system of the

tractor.

3-21 REAR IMPACT GUARD SYSTEM

Vehicle standards FMVSS No. 224, Rear Im-

pact Protection, requires all 336 Series trailers

manufactured after January 26, 1998 to be

equipped with a rear impact guard certified by the

manufacturer as meeting FMVSS No. 223, Rear

Impact Guards. The guard, or bumper,

(See Fig-

ure 3 -13)

, meets the following requirements:

·

minimum of 4 inches vertical height

·

extend laterally to within 4 inches of the

sides of the trailers

·

ground clearance of no more than 22 inches

·

placed no more than 12 inches from the rear

of the trailer

·

capable to deflect 5 inches

The standard also specifies minimum force and

energy absorption requirements for the guard. A

DOT decal certifies that the guard meets FMVSS

No. 223 and 224 standards. The decal is placed

and must remain at all times

on the forward fac-

ing surface of the guard, 12 inches inboard of the

curbside and of the guard.

See Figure 3-13

for lo-

cation of decals.

Replace any component that does not allow

the above minimum requirements to be met. Any

hardware that holds the rear impact guard and be-

comes damaged or becomes loose shall be re-

moved and replaced. The 3/4" grade 8 screws that

hold the bumper energy pack shall be loctited and

torqued to 280 ft-lbs.

DANGER

ALWAYS CHECK THE CONDITION OF

THE REAR IMPACT GUARD SYSTEM.

IF GUARD SYSTEM HAS BEEN DAM-

AGED, IT MUST BE REPLACED. FAIL-

URE TO MAINTAIN GUARD SYSTEM

MAY RESULT IN INJURY OR DEATH

TO OTHERS.

3-19

Содержание 336C

Страница 3: ...MODEL 336C CAR CARRIER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO...

Страница 8: ......

Страница 24: ...3 12 Figure 3 7 Lining Up the Over the Cab Deck Figure 3 8 Loading the Over the Cab Deck...

Страница 28: ...3 16 Figure 3 11 Loading the Lower Deck...

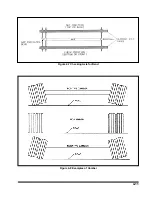

Страница 32: ...3 20 Figure 3 13 Rear Impact Guard and Antilock Brake System...

Страница 40: ...4 6 Figure 4 3 336C Wiring Diagram...

Страница 45: ...4 11 Figure 4 7 Checking Axle for Bend Figure 4 8 Examples of Camber...

Страница 50: ...4 16 Figure 4 12 Axle and Brake Assembly...

Страница 54: ...4 20 Figure 4 14 Outboard Mount Hub and Drum Figure 4 15 Inboard Mount Hub and Drum...

Страница 59: ...4 25 Figure 4 19 Mounting Tires and Wheels Figure 4 20 Stud Tightening Sequence...

Страница 70: ...NOTES 5 10...