WARNING

THE SPRING BRAKE CHAMBER EM-

PLOYS A SPRING WITH HIGH FORCES.

SERVICE SHOULD NOT BE AT-

TEMPTED. SERIOUS INJURY OR

DEATH MAY RESULT.

4-9.3

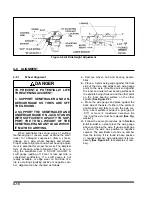

Replacing the Spring Air Brake Unit

a. Caging the Power Spring in the Spring

Chamber

1.

Chock the semitrailer wheels.

2.

Remove dust cap from the rear of the spring

brake chamber

(See Figure 4-12)

.

3.

Remove the release bolt from it’s holding

brackets. Insert it into the spring brake

chamber until it can be rotated and hooked

into place.

DO NOT USE AN IMPACT

WRENCH TO CAGE THE SPRING

BRAKE!

4.

Turn the nut on the release bolt until the

spring brake is caged. This should be 2-1/4

to 2-1/2 inches of release bolt extension.

5.

The brakes should now be released. Do not

operate loaded semitrailer with brakes

manually released.

b. Uncaging the Power Spring in the Spring

Chamber

1.

Insure the semitrailer wheels are chocked.

2.

Turn the nut on the release bolt until the

spring is released. Remove the release bolt

and store it in its brackets.

3.

Snap the dust cap back in place on the

chamber.

c. Removal of Brake Unit

1.

Chock all tractor and semitrailer wheels

and drain the air system.

2.

Mark the brake chamber for proper air line

port alignment for reassembly.

3. CAGE THE POWER SPRING

following the

steps outlined in

Section 4-9.3a.

4.

Disconnect the slack adjuster from the

connecting rod by removing the clevis pin

(See Figure 4-13).

5.

Mark all air service lines for proper

re-installation and disconnect from the brake

chamber.

6.

Remove the brake chamber from the axle

brackets.

d. Installation of Brake Unit

1. CAGE THE POWER SPRING f

ollowing

the steps outlined

in Section 4-9.3a.

2.

Position the inlet ports by loosening the

service chamber clamp bands and rotating

the center housing so the ports align with

marks made during disassembly. Then

re-tighten the clamp bands.

3.

Remount the brake unit on the axle

brackets and reconnect the air service

hoses and the slack adjuster connecting

rod

(See Figure 4-13).

IMPORTANT

BE SURE THE SERVICE LINE IS ON THE SERV-

ICE CHAMBER PORT AND THE EMERGENCY

LINE IS ON THE SPRING BRAKE PORT.

e.

Check for leakage by charging the air sys-

tem to a minimum of 90 psi and applying

soap suds to the brake chamber and connec-

tions. If a growing bubble is detected or bub-

bles are blown away, locate the source of the

leak and repair.

f.

Insure that the clamp band is properly

seated and tight

before

uncaging the power

spring.

g.

Uncage the power spring according to

Sec-

tion 4-9.3b.

4-9.4

Tandem Relay Valve Maintenance

Every 3600 operating hours, 100,000 miles, or

yearly, the Relay Emergency Valve should be dis-

assembled, cleaned, and lubricated by a trained

technician.

WARNING

REPAIR OR REPLACEMENT OF THE

RELAY/EMERGENCY VALVE IS A COM-

PLEX OPERATION AND SHOULD BE

PERFORMED BY TRAINED SERVICE

PERSONNEL. CONTACT A LANDOLL

AUTHORIZED SERVICE CENTER FOR

SERVICING.

4-14

Содержание 336C

Страница 3: ...MODEL 336C CAR CARRIER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO...

Страница 8: ......

Страница 24: ...3 12 Figure 3 7 Lining Up the Over the Cab Deck Figure 3 8 Loading the Over the Cab Deck...

Страница 28: ...3 16 Figure 3 11 Loading the Lower Deck...

Страница 32: ...3 20 Figure 3 13 Rear Impact Guard and Antilock Brake System...

Страница 40: ...4 6 Figure 4 3 336C Wiring Diagram...

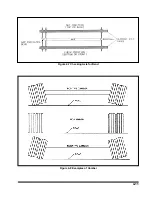

Страница 45: ...4 11 Figure 4 7 Checking Axle for Bend Figure 4 8 Examples of Camber...

Страница 50: ...4 16 Figure 4 12 Axle and Brake Assembly...

Страница 54: ...4 20 Figure 4 14 Outboard Mount Hub and Drum Figure 4 15 Inboard Mount Hub and Drum...

Страница 59: ...4 25 Figure 4 19 Mounting Tires and Wheels Figure 4 20 Stud Tightening Sequence...

Страница 70: ...NOTES 5 10...