104

8

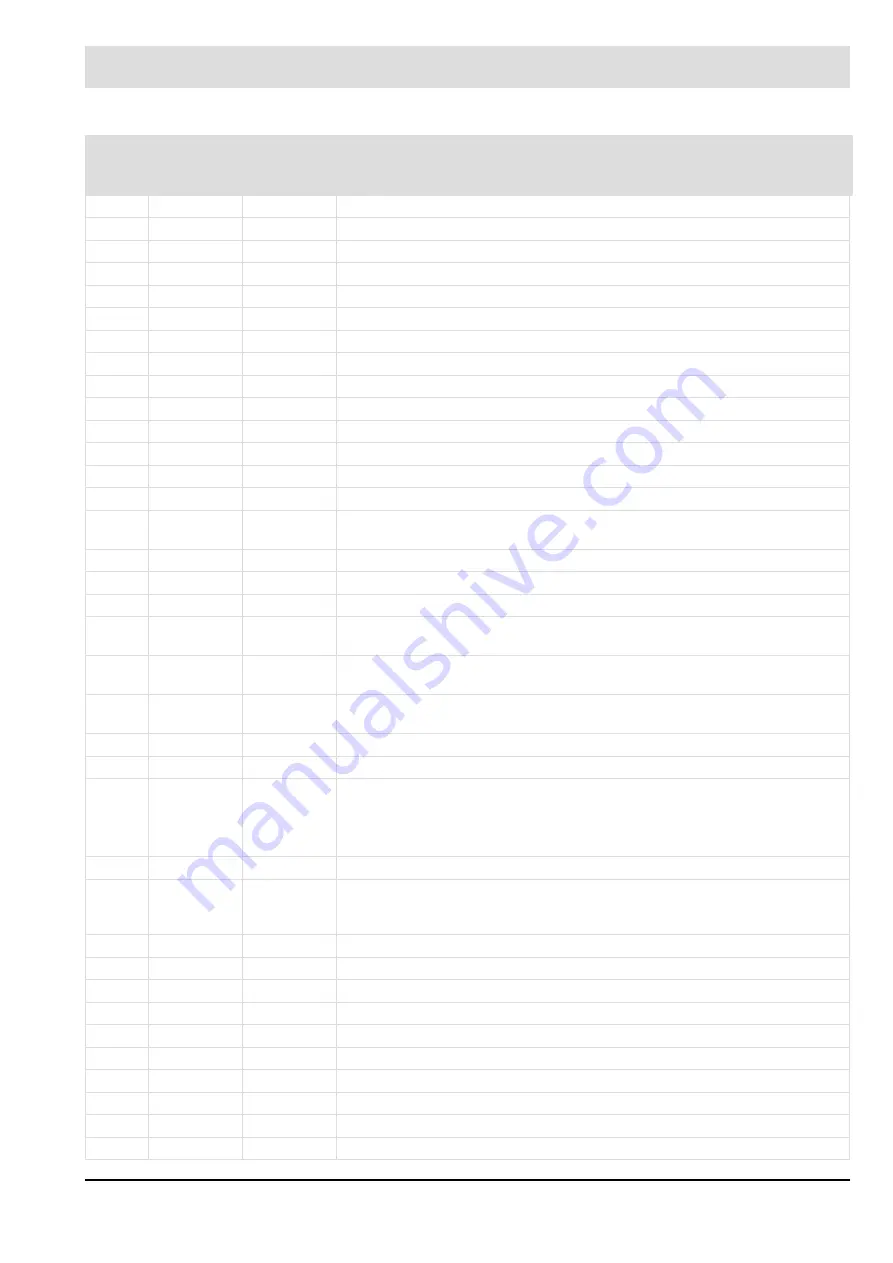

System Operation

Fault

Code

No.

Restart according to

Description

TRD

EN676

745

0

0

Programme check time exceeded.

Ü

746

0

0

Solenoid value switch-off faulty

Ü

747

0

0

Leak check: ventilating into boiler not allowed

Ü

750

0

0

Shut-down on faults via bus.

Ü

751

>88

3

No data transfer via the bus (time-out).

Ü

759

0

0

The "Setting" operating mode exceeded the 24-hour time limit.

760

0

0

Change of curve selection during setting not allowed

H/Ü

761

0

0

Change of curve lasts too long

The curve set change takes too long/could not be performed.

e.g.: The fuel safety chain is missing

763

0

0

different curve selection between the processors

764

1

1

CO-Controller, internal fault no. -

765

0

0

Parameter setting error: The channel for solo-fuel is not to determine.

Check the parametrisation of the channel configuration.

766

0

0

The limited firing rate (maximum firing rate without additional-fuel) does not

exists in the priority curves

Check the programming of the priority curves (assignment of the fuel channels and

their programming).

767

0

0

One parameter of the interpolation type for non-fuels is invalid

Check parameters 390 through 394

768

0

0

The curve set variable for the assigned air channel (1 = priority, 2 = additional

curve) is invalid.

Compare solo curves and priority curves as they possibly have different fir-

ing rate points!

769

0

0

Ignition while mixed fuel operation or burner-start with solo fuel-A

Ignition is permitted only in a solo curve set.

FMS:

Ignition is permitted only with the oil or gas solo curve set, but not with solo fuel A.

770

0

0

Fill-Time for fuel-A too long

791

>88

3

Bus master is in a stop.

Ü

792

>88

3

Bus data length incorrectly configured.

Ü

793

>88

3

Bus master is decoupled.

Ü

800

0

0

Error in parameters, for parameter no.:

H/Ü

888

0

0

Fault block activated !

Содержание VMS 4

Страница 1: ...www lamtec de Sensors and Systems for Combustion Technology Manual Fuel Air Ratio Control System VMS...

Страница 2: ......

Страница 119: ...118 10 Appendix...

Страница 121: ...120 10 Appendix 10 6 Process Sequence Charts Fig 10 3 Sequence of functions VMS digital inputs sequencer...

Страница 129: ...128 10 Appendix Fig 10 9 Ger t 4 Ger t 5 with output regulator...

Страница 141: ...140 10 Appendix 10 14 Declaration of Conformity...

Страница 142: ...141 10 Appendix...

Страница 143: ...142 10 Appendix 10 15 Protocol Example...

Страница 144: ...143 10 Appendix 10 16 O2 Setpoint Curves...

Страница 145: ...144 10 Appendix...