236

8

Options

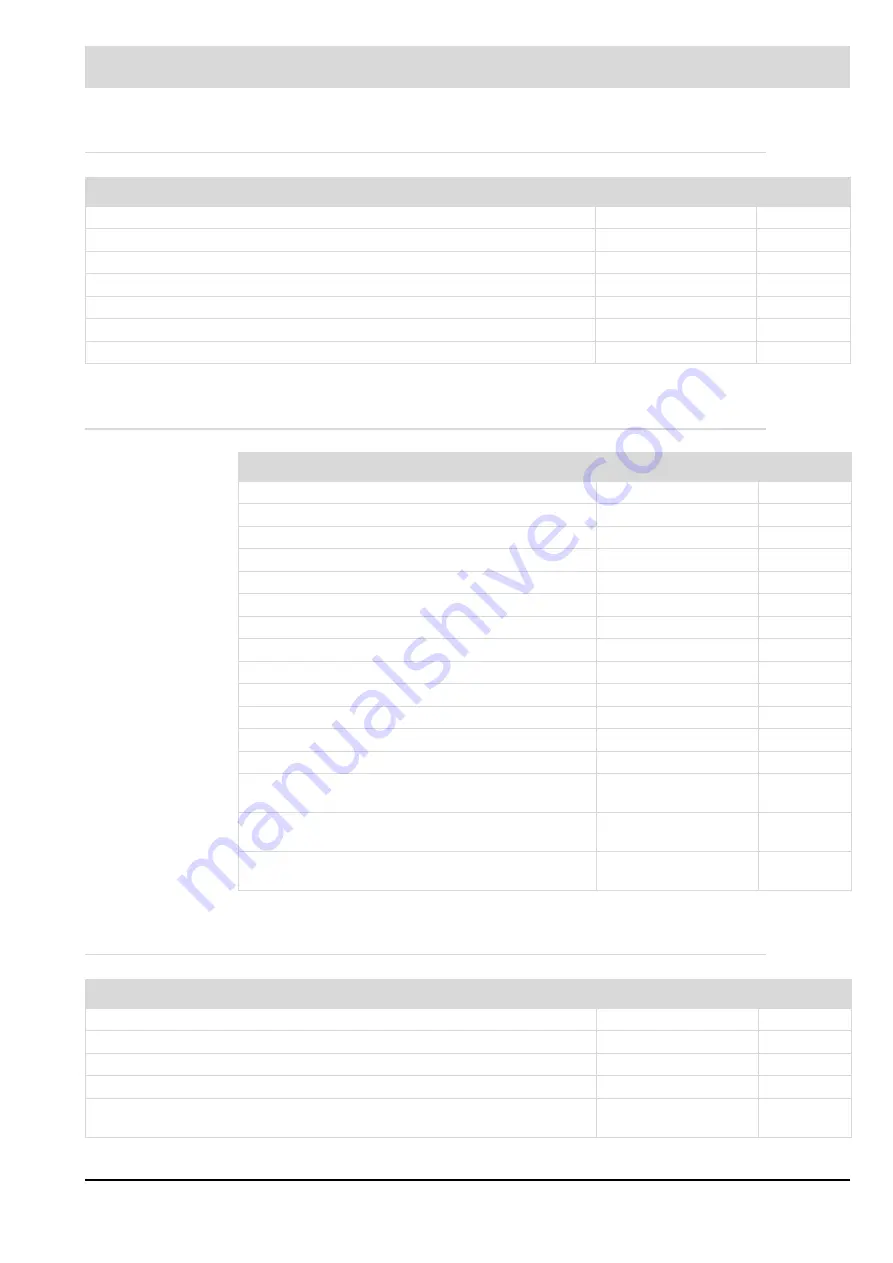

8.5.4.7 Bit Encoding: State of Actual Value of O

2

Tab. 8-17 Bit encoding: Status of O

2

actual value

8.5.4.8 Bit Encoding: Cause of Faults of O

2

Trim

Tab. 8-18 Bit encoding: Cause of faults of O

2

trim

8.5.4.9 Bit Encoding: Operating Mode of CO Controller

Tab. 8-19 Bit encoding: CO controller mode

Status of O

2

Actual Value

Bit Pattern

HEX Code

Underflow

0000 0010 0000 0000

0x0200

Overflow

0000 0100 0000 0000

0x0400

Maintenance mode

0000 1000 0000 0000

0x0800

Sending replacement value

0001 0000 0000 0000

0x1000

Warning of the measurement value

0010 0000 0000 0000

0x2000

Failure of the measurement value

0100 0000 0000 0000

0x4000

Invalid measurement value

1000 0000 0000 0000

0x8000

Cause of error

Bit Pattern

HEX Code

Not enough O

2

during pre-purge

0000 0000 0000 0001

0x0001

Too much O

2

during pre-purge

0000 0000 0000 0010

0x0002

Too much O

2

after ignition

0000 0000 0000 0100

0x0004

Static fault of probe dynamics

0000 0000 0000 1000

0x0008

Invalid setpoint curve in operation

0000 0000 0001 0000

0x0010

Invalid optimisation curve in operation

0000 0000 0010 0000

0x0020

Exceeding 1

st

upper monitoring band

0000 0000 0100 0000

0x0040

Exceeding 1

st

lower monitoring band

0000 0000 1000 0000

0x0080

Half of the air deficiency is pending

0000 0001 0000 0000

0x0100

- -

0000 0010 0000 0000

0x0200

Invalid O

2

actual value

0000 0100 0000 0000

0x0400

The firing rate is outside the range for control

0000 1000 0000 0000

0x0800

Static air deficiency is pending

0001 0000 0000 0000

0x1000

Dynamic measures for counteractions are active in air

deficiency

0010 0000 0000 0000

0x2000

Probe dynamics is missing. Dynamic measures for coun-

teractions is active to create probe dynamics.

0100 0000 0000 0000

0x4000

The controller outputs a correction value of more than

970 digit for more than 1 h.

1000 0000 0000 0000

0x8000

CO Controller Operating Mode

Bit Pattern

HEX Code

CO controller is OFF.

0000 0000 0000 0000

0x0000

CO controller is released in the current curve set.

0000 0000 0000 0001

0x0001

CO controller is ready for controlling the correction.

0000 0000 0000 0010

0x0002

CO controller takes control over the correction while the burner is running.

0000 0000 0000 0100

0x0004

CO controller transfers the value for inactive correction because the O

2

trim may

not take control.

0000 0000 0000 1000

0x0008

Содержание BT300 BurnerTronic

Страница 2: ......

Страница 21: ...20 3 Product Description Fig 3 3 UI300 and Fig 3 4 UI300 and dimensional drawings Fig 3 5 UI300 panel cut out...

Страница 25: ...24 3 Product Description Fig 3 9 Temperature derating BT300 for operation 2000 m NHN...

Страница 49: ...48 4 Design and Functions Fig 4 20 Oil with pilot burner BT300...

Страница 50: ...49 4 Design and Functions Fig 4 21 Oil without pilot burner BT300...

Страница 51: ...50 4 Design and Functions Fig 4 22 Gas with pilot burner and leakage test BT300...

Страница 52: ...51 4 Design and Functions Fig 4 23 Gas without pilot burner and leakage test BT300...

Страница 53: ...52 4 Design and Functions Fig 4 24 Oil without pilot burner BT335...

Страница 54: ...53 4 Design and Functions Fig 4 25 Gas without pilot burner and leakage test BT335...

Страница 59: ...58 4 Design and Functions Fig 4 28 Leakage test process diagram...

Страница 98: ...97 6 Operating Control and Displays...

Страница 99: ...98 6 Operating Control and Displays...

Страница 102: ...101 6 Operating Control and Displays NOTICE If the license agreements are not accepted the installation is aborted...

Страница 103: ...102 6 Operating Control and Displays...

Страница 105: ...104 6 Operating Control and Displays...

Страница 106: ...105 6 Operating Control and Displays...

Страница 107: ...106 6 Operating Control and Displays...

Страница 109: ...108 6 Operating Control and Displays...

Страница 126: ...125 6 Operating Control and Displays 6 3 4 2 Curve Table Fig 6 37 Curve table window...

Страница 246: ...242 10 EU Declaration of Conformity 10 EU Declaration of Conformity...

Страница 247: ...243 10 EU Declaration of Conformity...

Страница 248: ...244 10 EU Declaration of Conformity...