Lake Shore Model 647 Magnet Power Supply User’s Manual

Options & Accessories

6-2

in the mechanical orientation or in the direction of either the magnetic field or the control current will result in a

polarity change of the output voltage.

The active area of the Model HGCA-3020 Axial Hall Sensor is approximately 0.03 inch in diameter in the

center of the face opposite the leads. When the control current is applied with the red lead positive with

respect to the black lead, and the magnetic field is perpendicular into the face of the probe opposite the

leads, the Hall voltage is positive at the blue lead with respect to the yellow lead. Again, a reversal in

mechanical orientation or in the direction of either the magnetic field or control current results in a output

voltage polarity change.

Handle the Hall sensor with care. The ceramic substrate is brittle and very sensitive to bending stress. Mount

the sensor to minimize mechanical strains as the sensor cools. Failure rates approaching 10% occur on initial

cool down with improperly installed sensors (sensors surviving initial cool down generally experience no

problems on subsequent cycles). Avoid applying tension to the leads. Bend the leads at any angle so long as

the bend is at least 0.125 inch away from the substrate connection. Mount the device to a non-flexible,

smooth surface with a coefficient of thermal expansion no greater than a factor of three different from that of

the ceramic substrate (about 7 x 10

-6

in/in per K).

Locate the probe in a cavity that is 0.003 inch wider and 0.01 inch longer than the substrate, and with a depth

the same or slightly greater than the thickness of the package. Tack the leads outside the slot with GE-7031

varnish or other similar substance. Sparingly apply the mounting substance to the corners or a dot on each

side of the sensor to hold it in place. Avoid applying mounting substance on top of the sensor. Alternately, use

Kapton

®

tape or a mechanical cover over the top of the sensor to keep it in place. The tape or cover should

apply only light pressure to the sensor. If epoxy is the mounting substance, use it sparingly and use the same

type as is used in the sensor, Stycast

®

2850-FT epoxy. Never pot the probe.

A room temperature calibration over the range of ±30 kG comes with each probe. The calibration specifies

the terminating resistor (not included) required to maintain an accuracy of ±1% of reading up to ±30 kG and

±2% of reading up to ±150 kG over the entire temperature range. For a terminating resistor, use a metal film

resistor with 1% or better accuracy mounted across the output voltage leads as close to the probe as is

practical. To extend the leads, use AWG 34 stranded copper with Teflon insulation (the same wire used on

the probe). Any impedance in the output leads acts as a voltage divider with the terminating resistor. Probe

reading reproducibility is within ±1% over repeated thermal cycling between 4.2 K and room temperature.

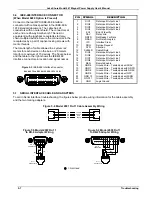

6.2.2 Connections

The Model 6476 has one rear panel 9-pin connector to interface with the

level and field probes. See Table 6-1 to the right.

6.2.3 Installation

The 6476 Gaussmeter Input Option is factory-installed if ordered with a

MPS or may be field installed at a later date. For field installation, use the

procedure below:

WARNING

• This procedure is intended for trained service personnel who

understand electronic circuitry and the hazards involved. Do not

attempt this procedure unless qualified.

• To prevent shock hazard, turn off the instrument and disconnect

AC line power and all test equipment before removing cover.

1.

Turn off the MPS and disconnect the power cord.

2.

Locate the Optional Plug-In Board Slots on the MPS rear panel. Loosen the two screws that secure one

of the blank cover plates and remove the cover plate.

3.

Slide the Model 6476 board into the MPS with the board handle towards the bottom of the MPS. Tighten

the two screws that secure the board to the MPS rear panel.

Terminal Description

1

2

3

4

5

6

7

8

9

Field –Current

Field –Voltage

Field +Voltage

Field +Current

Shield

Not Used

Not Used

Not Used

Not Used

Table 6-1

Model 6476 Connections